Maersk Line and Implement Consulting Group

4 April 2018

Maersk Line ahead of competition

For years, Maersk Line has established itself as market leader with EBIT growth that is > 5 % higher than that of its competitors. This has partly been achieved by a reduction in unit costs through strategic initiatives such as slow steaming, larger vessels (economies of scale) and strategic partnerships. Maersk Line seeks to continuously improve; however, their innovations are also copied by competitors.

The Future Operations Execution (FOE) transformation programme was initiated in 2013 with the purpose of developing Maersk Line Operations Execution in order to achieve a unique competitive advantage: Operations that continuously drive costs down through standardisation and systemic process improvements.

Maersk Line Operations Execution

Maersk Line Operations Execution is managing the world’s largest fleet of more than 500 vessels with the objective to deliver what their customers have promised to their customers at the lowest possible operating costs. The main processes of Operations Execution are capacity planning, cargo execution, marine management and procurement. The organisation spans across 8 regional offices and 3 service centres working together in one global network.

The vision of Future Operations Execution

Before FOE, the primary driver was the performance of the individual regional locations. The result was a highly competitive internal environment. The eight locations did not follow global standards, but optimised their own processes, performance data, organisational structure and way of working. There was little motivation for sharing best practices, even though customers as well as the company’s bottom line were dependent on a high-performing network for global container shipping.

The FOE programme set out to change this through defining and implementing:

- One set of numbers

- One way of managing

- One set of processes

- One global organisation

- One continuous improvement mindset

This simple but strong message was broken down into a simple model for how Maersk Line was to succeed with the mission.

Overall end-2-end improvement model

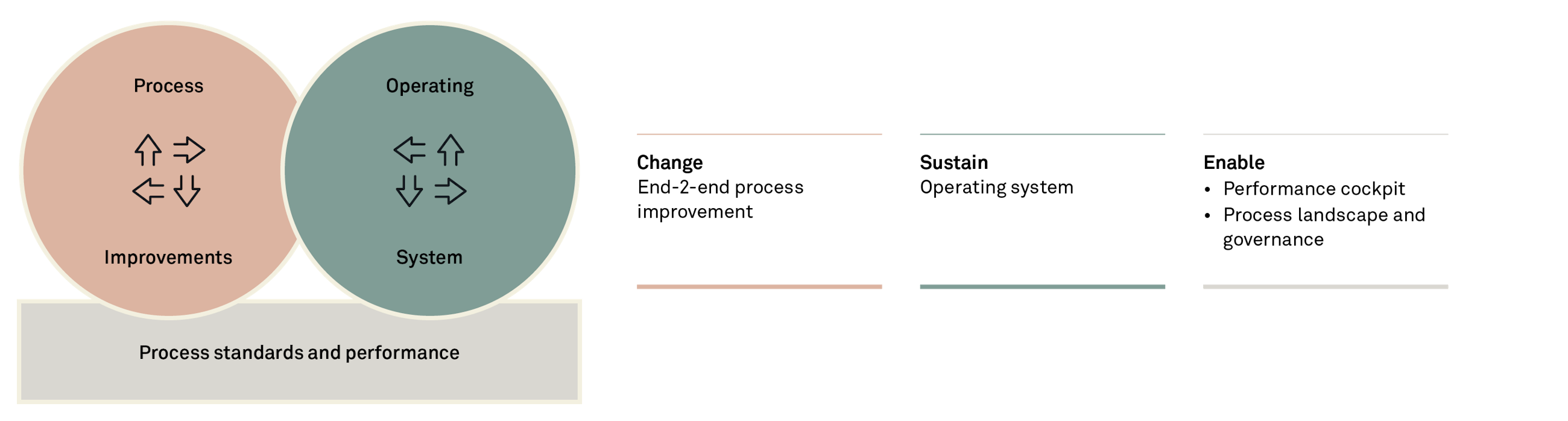

The FOE programme focuses on three components: enable, change and sustain to drive Maersk Line towards world-class operational execution.

1. Enable

Designing the best process improvements and management systems in the world will never have the desired impact if the right infrastructure is not in place to support the change. Maersk Line had two major achievements, implementing a global performance cockpit and mapping out the process landscape. The cockpit is a global IT tool for making performance measures readily available for the frontline and management. The process landscape acts as one source for process improvement, communication, training and documentation.

Process landscape

When improving processes across the value stream, how you document, structure and govern the processes becomes a key enabler for implementing and sustaining change. The process landscape enables Maersk Line to have a shared global view on different levels in the process hierarchy from end-2-end to detailed swim lanes, SOPs and checklists. The process landscape will only cater for one global standard. However, due to specific regional requirements, local adjustments of up to 20% of an SOP are allowed. These local adjustments are also housed in the global process landscape as agreed exceptions.

Maersk Line has achieved:

- One global process landscape with drill-down capabilities to the lowest levels, e.g. SOP and checklists in an easily accessible system (iGrafix).

- Unique process references for all steps at SOP level to enable clear and structured process governance globally.

- A governance structure with global process owners placed locally as part of a global governance network.

The details of the process landscape are gradually being developed, acting as one global source of process documentation and enabling governance of the global process landscape.

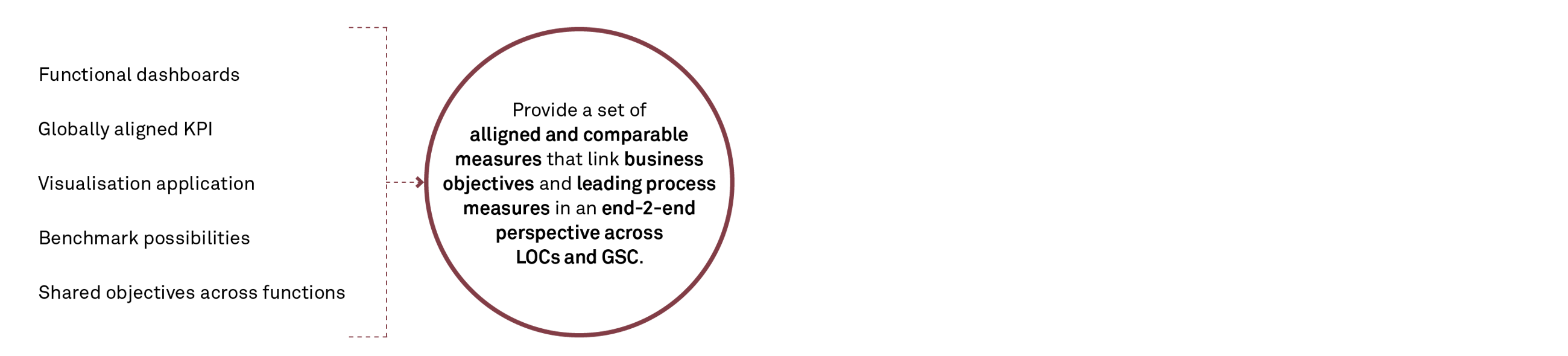

Performance cockpit

The mission is to consistently drive down costs through continuous improvement. How Maersk Line measures performance is a key enabler. This deliverable was set out to align objectives, standardise measures and definitions globally and provide an easily accessible global performance cockpit.

Maersk Line has achieved:

- Globally aligned definitions. One source of data for all operational measures and data.

- Defined global standard dashboards for each function to support daily and weekly performance meetings.

- Drill-down capabilities to e.g. container and vessel level to identify root causes.

- Shared and standardised objectives at all management levels divided into running and improving the business.

The cockpit is dynamic, which means that when a new process has been designed, important process performance measures are included in the cockpit in order to realise the change and the benefits.

2. Improve

Improving processes in a global context is not an easy task. A structure and tact of three months in the improvement cycles have ensured that management has set a clear ambition for the change, that SMEs across the functions have been a part of the design, and that local training and implementation are carried out effectively. Two different approaches to improving the global process landscape have been applied, i.e. Improvement cycles (I-cycles) and Standardisation cycles (S-cycles).

Improvement cycles

An I-cycle is the improvement process for large end-2-end improvements, securing significant lead time and cost reductions. With focus on lead time, cross-value stream I-cycles are run, mapping current state (based on the process landscape and the performance cockpit), identifying improvements, co-creating the solutions and setting the global business case. And lastly, it ensures global implementation of the new and improved processes.

Maersk Line has achieved:

- Roll-out of standardised end-2-end improvement cycles to identify and design process changes in a structured and methodical manner.

- Train the trainer workshops at all locations to continuously train the end users effectively in the new global SOPs and checklists.

- Handover of new processes to the local management/operating system by setting up process measures and process confirmations to sustain the new processes.

I-cycles have been and still are a key driver for realising significant reductions in behavioural costs.

Standardisation cycle

An S-cycle is the improvement process for standardising parts of the process landscape to harvest best practices and ensuring a solid foundation for further improvement.

S-cycles are a “light” version of the I-cycles, reducing time spent on e.g. designing and building business cases. S-cycles are a quick-win for Maersk Line to benefit globally from already implemented best practices from one location.

Maersk Line has achieved:

- A leap in globally standardised processes, building one global process landscape at a fast pace.

- A new language and culture that have put standardisation on the agenda.

Improving globally is very difficult if you manage operations completely differently across locations and functions. The operating system will ensure that each team, function and the network overall sustain (and improve) the process improvements.

3. Sustain

Why an operating system?

All organisations have an operating system – whether it is designed deliberately or at random, and whether the standard is articulated or not. The quality and level of standardisation makes a difference. The Maersk Line operating system is divided into two focus areas:

- Running the business: Long-term and short-term planning, daily task execution and status on performance.

- Improving the business: Focus on initiatives to improve the business from minor ideas to bigger projects and developing employee skills/ competences.

Having a standardised operating system in place results in increasing performance levels, while also enabling the organisation to implement and sustain change faster.

Operating system within Maersk Line Operations Execution

When FOE started, the operating system was not standardised and mature enough to handle the transformation that the FOE programme entailed. Thus, the design of the new operating system focused on improving the existing one, but also standardising it across teams and geographical locations to ensure that change will be sustained in the local environments.

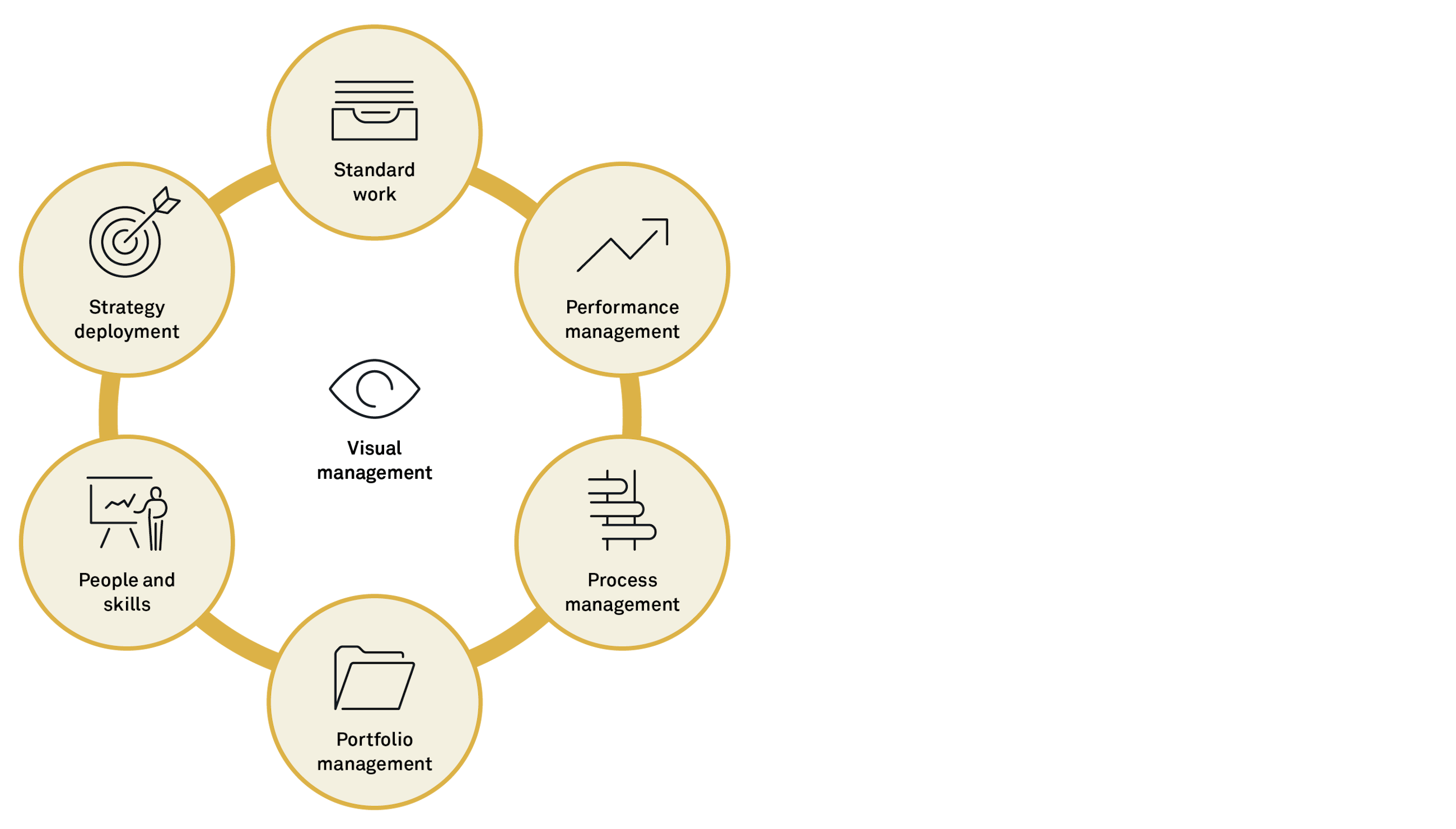

The operating system consists of six elements that are all supported by visual management. It is important that it is perceived as one system and not as six individual elements. The six elements are:

Standard work

A global standardised meeting structure, including content, sequence and frequency. The scope ranges from top management to daily team stand-ups.

Performance management

Standardising reporting and business performance dialogue. Applying leading measures in daily execution to impact business performance.

Process management

Managing the organisation’s process performance to secure standardisation and a foundation for improving processes through I-cycles and S-cycles.

Transformation management

Improve business performance through projects running in the local organisations or improvement ideas handled within the team. Includes portfolio governance of locally initiated projects and initiatives from headquarters.

People and skills

Focus on people and the development of functional skills and competences, supported by effective training based on standardised processes in the landscape. Supports I-cycles and S-cycles in training in new processes to secure faster implementation and thus standardisation.

Strategy deployment

Deploying must-win battles from headquarters a to ensure consistency between the daily efforts and the overall strategic goals.

Measuring maturity for development

The operating system is supported by a maturity assessment in order to maintain a continuous focus on developing the operating system of each function and location. The assessment ensures a systematic development of the local organisations and the organisation as a whole, which is the key to continuously improve performance and beat competition.

The assessment is based on defined criteria from maturity level 1-5 per element in the operating system. The maturity assessment is the glue that ensures that the organisation across functions and locations is developing in the same direction.

Impact

One global organisation adhering to standard, performing to standard and improving the standard with the ambition to improve and deploy a new standard within 24 hours worldwide. Quarterly end-2-end I-cycles securing triple-digit USD million bottom-line impact year on year. One way of managing through a mature operating system. Increasing productivity, effectiveness and sustaining the roll-out of global process improvements. The short-term financial benefit is significant, but the real long-term accomplishment is a learning and agile operations, not only based on excellently skilled people, but also on a world-class system that is continuously improving.