Linking emissions with decisions

16 December 2021

Many companies are committed to reducing greenhouse gas emissions and have started initiatives inspired by the UN Sustainable Development Goals and the Paris Agreement to reduce emissions to limit global warming to 1.5°C. In addition to having separate emission reduction initiatives, companies must also anchor their strategic sustainability goals in their day-to-day decisions. And rather than carrying out isolated and sometimes uncoordinated initiatives, supply chains are the place to start, since supply chains often contribute to most of the emissions of a company.

In the sales and operations planning process (S&OP), companies identify gaps between demand and supply, and this process in the supply chain should also be the means of comparing what you expect to achieve in the future with the goals you need to reach from the strategic target-setting process.

In this article, we would like to show the potential of sustainable sales and operations planning (Sustainable S&OP). Sustainable S&OP is the sustainable layer that can be integrated into the normal S&OP process. By initiating the Sustainable S&OP process, you can make and execute decisions, ensuring the most sustainable output of your company based on the current state of the business. These decisions are highly linked to both the operational targets and the sustainability strategy, which will improve the output and increase the visibility of the implications of an action – linking emissions with decisions.

Consider maturity when setting your goals

To incorporate sustainability-driven decisions in your S&OP process, you must make the following preparation:

- Have an established S&OP process and an ambition to bring it to the next level

- Formulate sustainability ambitions to be turned into concrete targets

- Acknowledge that measuring your carbon baseline is a journey

S&OP considerations

In order to incorporate sustainability in your S&OP process, you must make a realistic assessment of how mature your company is. Do you agree on one set of numbers? Do you spend meetings focusing on the S&OP horizon and not on what happened yesterday or what will happen tomorrow morning? If you do not focus on the S&OP horizon in the meetings, then adding sustainability will most likely not add any value, since the basic maturity is not in place.

For effective S&OP meetings and decisions, it is important that you cooperate cross-functionally and that you make decisions based on facts and not on who last did you a favour or which sales region shouts the loudest. Adding the sustainability dimension to your S&OP process contributes to a holistic picture, and the more holistically and cross-functionally your decisions are made today, the easier it will be to incorporate the sustainability dimension in the future decision-making process and transform your process into Sustainable S&OP.

You can use data and systems to support the S&OP process but only to the extent that the decision-makers trust the numbers in the system. To “carbonise” your plan (getting emission factors into the plan), it is important that you are transparent about what you know, what is based on facts, and what is based on assumptions. The more end-to-end you can model your supply chain today in a planning system, the more accurately you can carbonise the plan.

Finally, the feedback we get from customers is that it is difficult to anchor the S&OP process at the executive level. Monetising the plan has helped some companies, but since a lot of company strategies today include different sustainability goals, then carbonising the plan is a way to get more executive attention and visualise the carbon emission impact of decisions made in S&OP meetings.

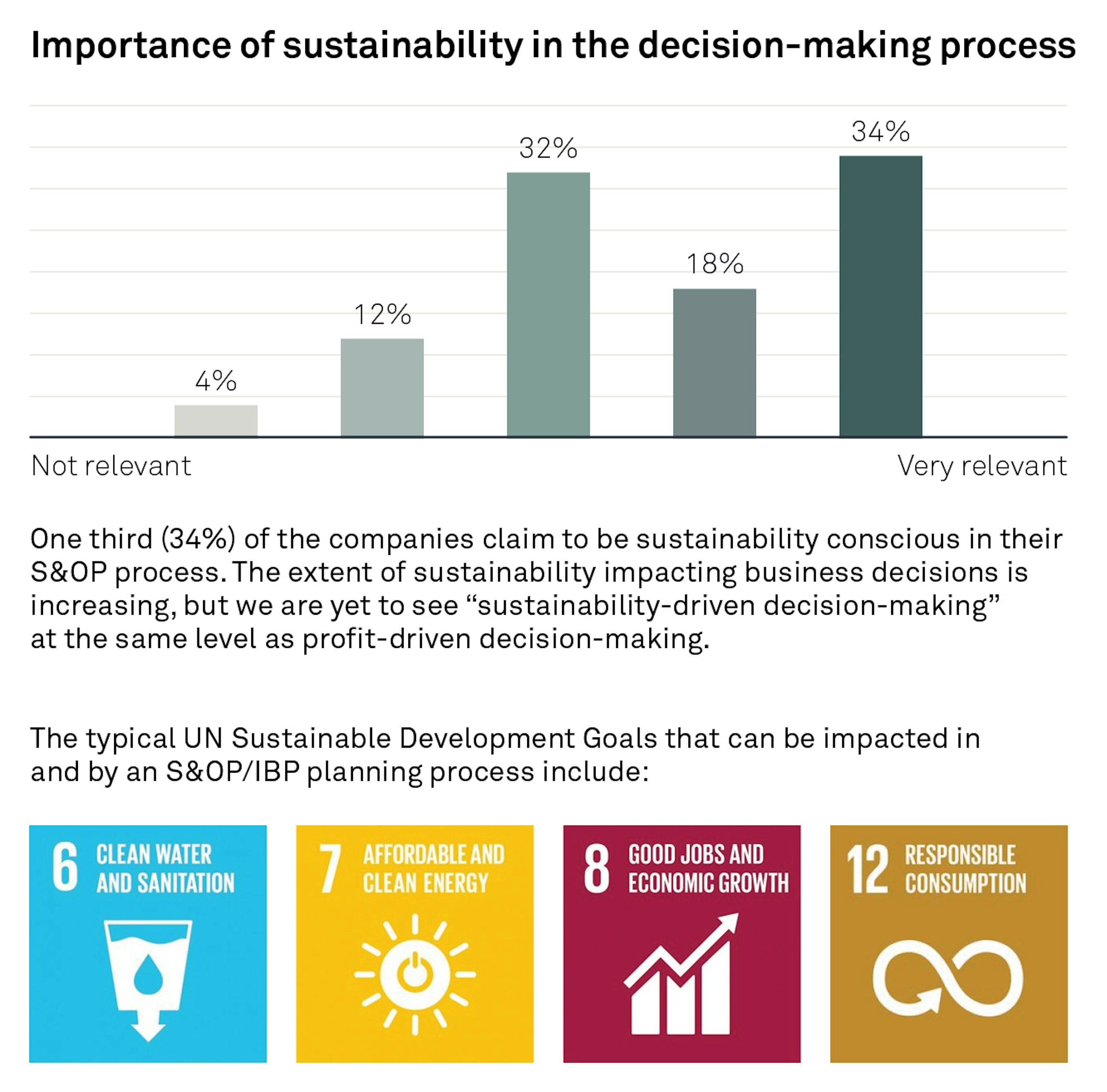

Back in 2020, Implement conducted a survey on the maturity of the S&OP process of companies and to what extent sustainability was important to the decision-making process. 52% said that it was relevant or very relevant. Yet, the extent of sustainability impacting business decisions has not reached the same level as profit-driven decision-making. However, we see that this trend will change in the future, and it will be a combination of both profit-driven and sustainability-driven metrics that will impact future decision-making in the Sustainable S&OP process.

Turn your sustainability ambitions into concrete targets

In the strategy process, many companies have set sustainability ambitions of what they want to achieve in the future. You should turn these ambitions into targets, e.g. in 2 years, 20% of your products should be made from recycled materials, 50% of transport should be by ship or non-fossil trucks, 80% of our products should be locally sourced etc. By turning ambitions into concrete targets, you can use the Sustainable S&OP process to identify the gaps between what you expect to achieve and what your target is.

By having turned your strategic sustainability ambitions into concrete targets and having the Sustainable S&OP process in place, you are now able to measure expected carbon emissions, percentage of recycled materials, usage of different modes of transport etc. This enables you to get an understanding of what decisions you need to make to close the gap.

Acknowledge that measuring your carbon footprint is a journey

When you have the S&OP capabilities in place and know what sustainability target you have, you need to add sustainability measurements to your plan. Some data elements like recycled materials or percentage of electric transport might require less effort to get in place than carbonising your entire supply chain plan. The more end-to-end you plan your supply chain today and the more tiers you incorporate, the easier it is to be detailed about carbon emissions and the impact of your decisions. However, if your carbon footprint is based on qualified assumptions instead of an LCA, stay at the level of detail where the different assumptions impact the plan. For external sourcing vs. production in-house, estimate the split between modes of transport and emissions of finished goods based on average production methods and not resource dependency etc.

When making decisions based on the calculated carbon baseline, be clear on what is assumption-based and what is fact-based to maintain trust in the numbers. Indeed, when making decisions in the Sustainable S&OP process, it is better to just start with assumptions and take environmental impact into consideration than not start at all.

In the following section, we will deep dive into the concept of sustainable S&OP, look at what the different steps include and how it all links to a company’s sustainability strategy.

Integrate sustainability into your S&OP process by using the Sustainable S&OP model

The Sustainable S&OP process consists of five general steps:

- Product review

- Demand planning

- Supply planning

- Balancing and decision-making

- Execution

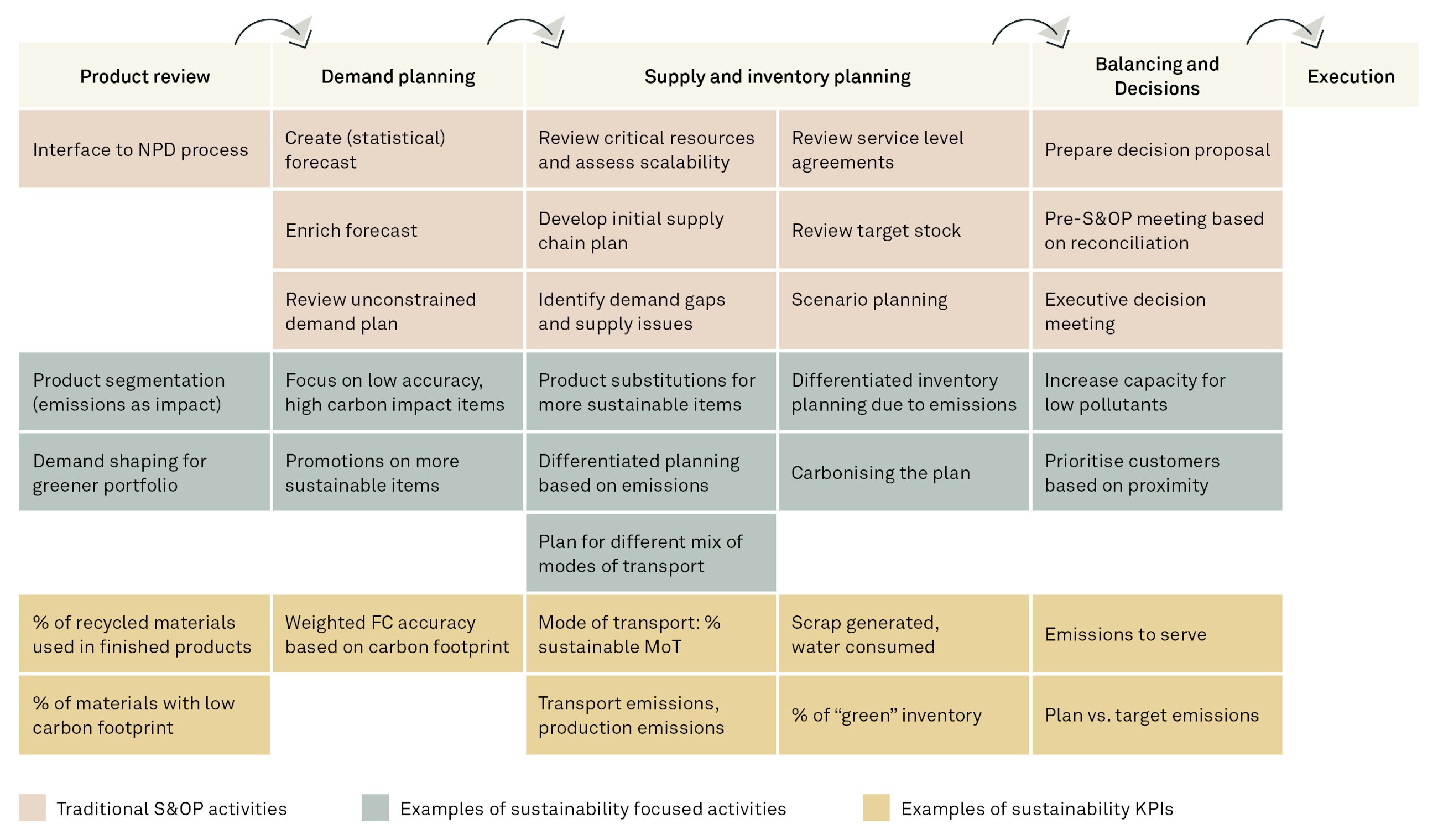

All five steps have a sustainability angle to the normal S&OP process steps (see figure below ).

The initiation of the process where you carbonise the demand plan (get emission factors into the plan) will create a demand plan with actual numbers to support sustainable decisions later in the process. These numbers will reflect emissions down to the level of detail that is preferable to your maturity and sustainability strategy. Later in the demand planning step, a product review and demand shaping based on emissions will create a more sustainable demand plan. On top of that, sales can do promotions that support the sustainability strategy and boost sales of the more sustainable product portfolio.

The supply planning part of the Sustainable S&OP process will support network breakdown, capacity and stock projection decisions. The output of supply planning is a carbonised plan which takes output volumes, mode of transport and fill rates, among other factors, into consideration, where the level of detail will be set based on the maturity of your company.

By having tangible numbers to evaluate the sustainability of the plan, you enable immense opportunities in the balancing and decision-making step of the Sustainable S&OP process. Scenario comparison of extra shifts, different sourcing alternatives and varying modes of transport will increase the visibility of the implications of an action. Also, you enable tracking of the overall emissions of your company, which is often linked to the overall strategy. You make prioritisations in constrained situations in the execution part of the Sustainable S&OP which uses formalised KPIs such as CO2e emissions and water consumption. Furthermore, by bridging the gap between emissions and decisions, you make it clear what the implications of an action will be. This ensures that in every situation where a decision is needed, the most sustainable action that still contributes to profitability can be chosen, ensuring that the plan is still followed and that it still supports the overall strategy of the company.

In the following section, we elaborate on how you embark on your Sustainable S&OP journey, depending on your current maturity and sustainability ambitions.

How to get started?

The next step of your Sustainable S&OP journey depends on your company’s sustainability and S&OP maturity. For companies with low maturity within both areas, this can make it overwhelming to embark on the Sustainable S&OP journey, while it can be more straightforward for companies with high maturity within the areas. The good news is that in both cases, there is progress to be made for your company. And the most important part is that you embark on the Sustainable S&OP journey.

If you do not know your current maturity situation, it can be valuable to assess as this forms the basis for defining your goals for the development of the Sustainable S&OP process. Based on your company’s current maturity level and depending on your company’s ambitions to become more sustainable, you can implement different initiatives of the Sustainable S&OP model.

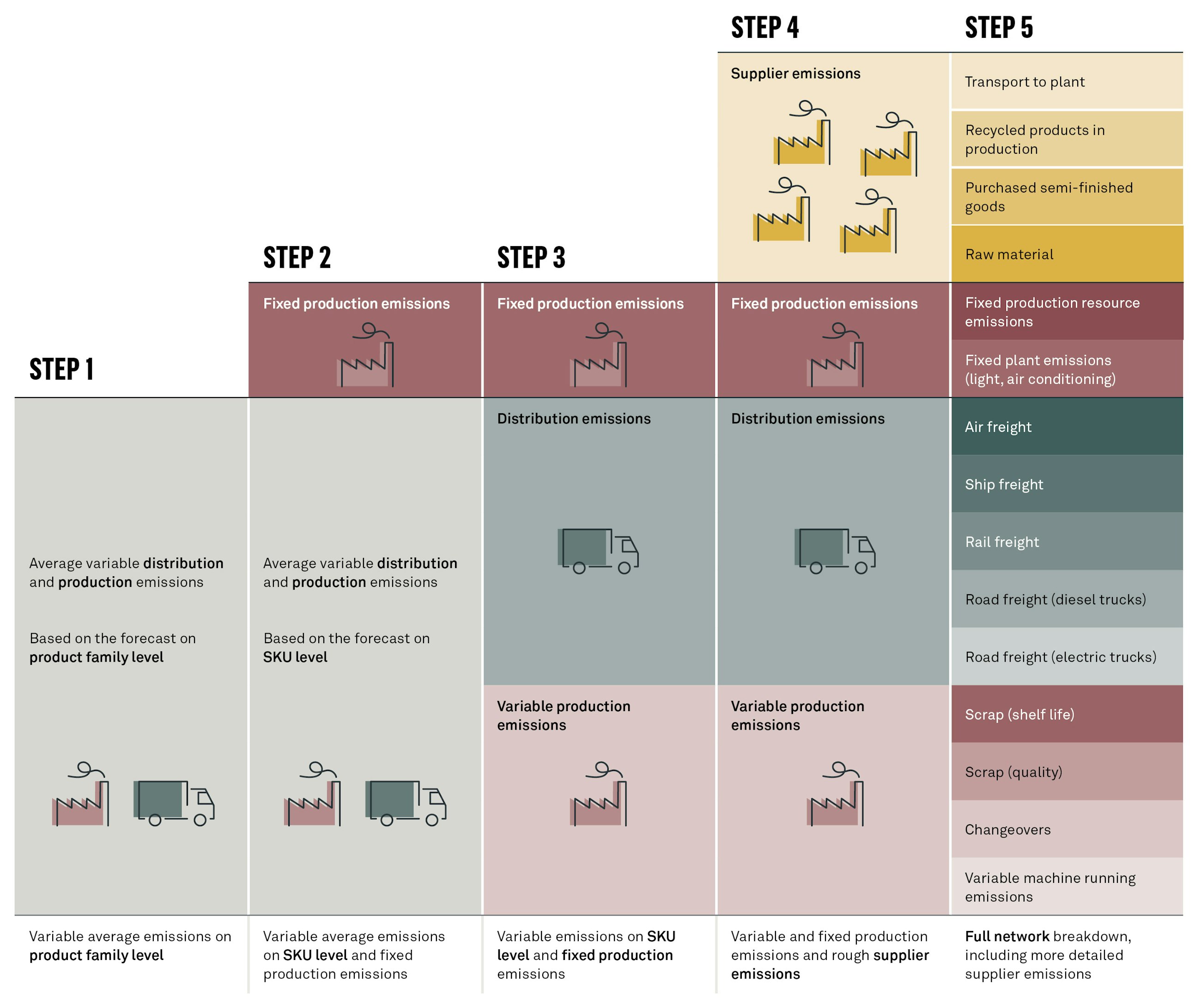

Taking the initiative of carbonising your plan as an example, companies that are just getting started could begin small by focusing on carbonising the demand plan (see step 1 in the picture below ). This can be based on assumptions or some simple average calculations in case of insufficient or lacking data. On the other hand, companies that aim at being best in class can continue their journey by moving towards taking a more advanced end-to-end approach. Here, the supply planning part is incorporated too, and more advanced measures are being used to determine where sustainability improvements in the supply chain can be made (see step 5 in the picture below ).

No matter where you are in your Sustainable S&OP journey, we advise you to aim at focusing on a few prioritised initiatives and KPIs where measures can be trusted, even if based on assumptions, which can be used for changing the focus to more sustainable S&OP decisions. Doing this, you ensure that your initiatives do not become redundant by focusing on too many things at the same time.

If you are in doubt about how to prioritise the Sustainable S&OP initiatives, one way could be to compare the different initiatives by conducting an impact-effort assessment to identify potential quick wins or areas of high effort due to lack of influence. When deciding on initiatives, it is also important that you consider the scope and whether any markets, product groups or parts of the supply chain should be used as a pilot. By using a pilot or limiting the scope, you can also ensure validation of the relevance of your chosen initiatives and KPIs early in the process.

When it comes to incorporating sustainability initiatives in your S&OP process, the number of options out there can be overwhelming and ultimately lead to not getting started at all. Yet, we need to acknowledge our responsibility for incorporating sustainability in our supply chains and start bringing sustainable facts into our day-to-day decisions. Hence, we see a huge potential in embarking on the Sustainable S&OP journey towards making your operations more sustainable and linking emissions with decisions.