– and how to cope with them

21 August 2019

When companies implement a Warehouse Management System (WMS), we see a number of different pitfalls. While some of the pitfalls may be represented to a greater extent in specific industries, you can use this blog post as a general reminder for your next WMS implementation to support you in mitigating risks and enhancing your possibilities for a successful WMS project.

We have not based the blog post on a major survey – but through 15 years of experience within warehouse projects, we firmly believe it will be beneficial for you to be aware of these pitfalls and assess your risk accordingly in your next or ongoing WMS project.

1. Treating the project as an IT project

Companies that implement a WMS sometimes tend to consider the project as a pure IT project, resulting in a limited focus on warehouse operations and a much higher focus on available functionality and features. This leads to a solution which in theory sounds great, but in reality, the efficiency of the warehouse operations is often reduced or stays the same.

A rule of thumb is that you always analyse the processes step by step and then build a WMS solution that supports and improves warehouse operations. You must remember that an out-of-the-box WMS does not bring any value on its own. You only get the benefits when there is a proper fit between operations and system.

2. Lack of engagement from other stakeholders

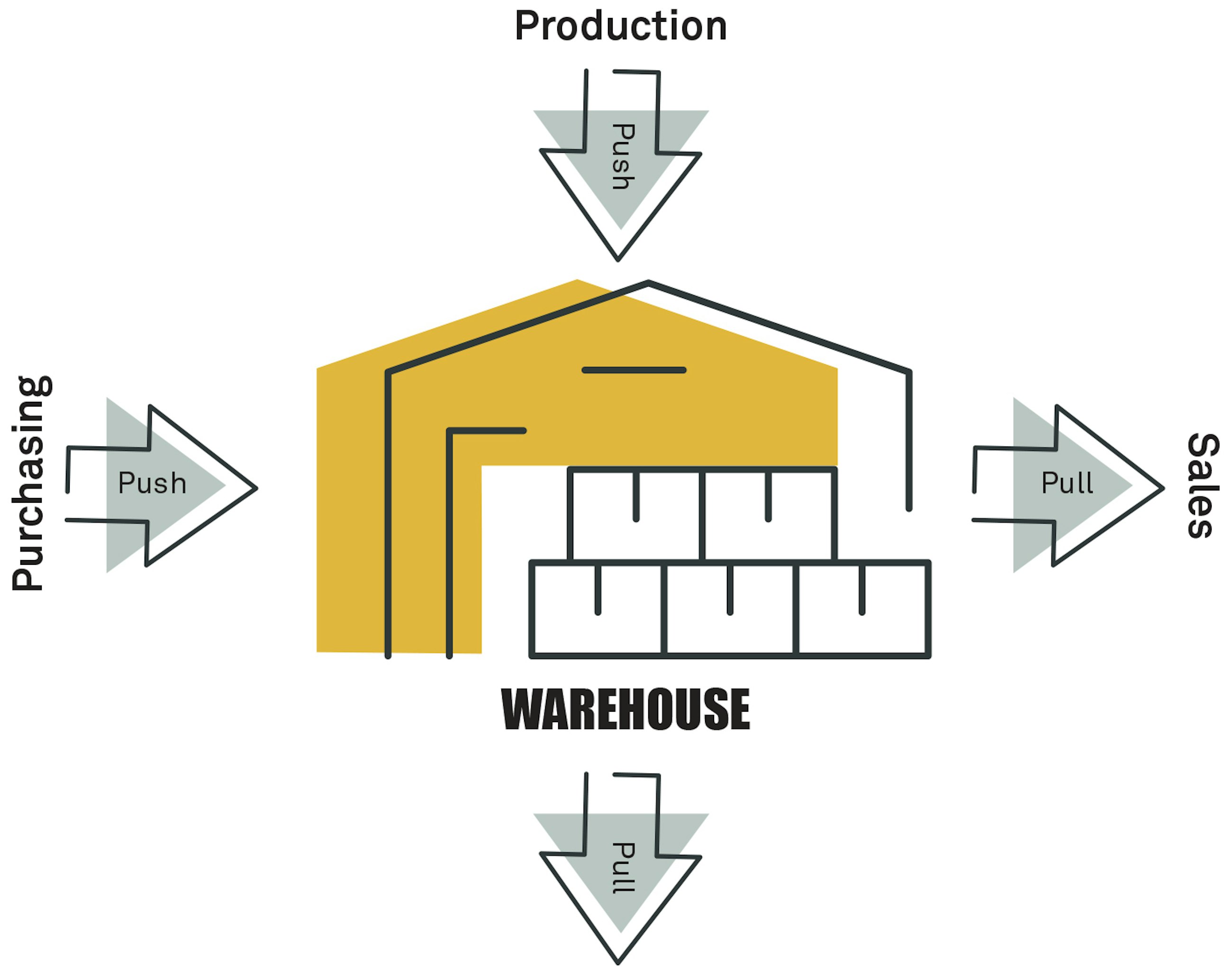

Your warehouse operations are highly dependent on other departments; purchasing, production, sales and – for some – also quality control.

These departments have direct impact on movements in the warehouse as shown above with push and pull triggers. When other departments are not involved in the project, they might not see the value of extra registration of e.g. master data and a new way of ordering goods for production and/or shipping. If this is the case, you risk missing buy-in from management and shop floor employees and face big challenges in the change management efforts.

For that reason, engagement and alignment between departments are key for your success when implementing WMS.

3. Hardware neglection (wi-fi spots, label printers, hand scanners, barcode labels etc.)

Companies often neglect hardware in the project plan, and – in some cases– this can cause a postponement of a go-live date. Essentially, if you have not made sure that all wi-fi spots are installed, or if label printers are not configured or delivered yet, your WMS can’t function.

We recommend involving the technical team early so they can explore different suppliers for test units prior to deciding and buying multiple hardware. Further, we also see that a practical activity such as ordering barcode labels can be a common pitfall due to neglection and delivery time if it is a major warehouse.

4. Neglection of language barriers

In projects in general, language is a common barrier when people from different countries work together. For WMS implementations, it is often an even bigger challenge. The warehouse workers may not be confident in speaking English, and the global project team may not be able to speak the local language. This can cause misunderstandings and generally slow down the progress during the project.

If possible, you can cope with this pitfall by pursuing to execute the project in the local language, or you can have a local middleman to help with translating and gathering information from the warehouse workers. Alternatively, you can involve specific warehouse employees with a higher level of English, although you should keep the training and other parts of the change management activities in the local language.

5. Lack of consideration for summer workers/churn of warehouse workers

Many warehouses often have temporary workers, e.g. during the summer period. Therefore, it is important that it doesn’t take too much time to train new workers in operating the WMS devices. If the devices or WMS solution are not intuitive, and if there are many unique processes and exceptions, it will be a cost driver for the warehouse.

You can cope with this by minimising complexity, i.e. minimising the amount of actions that can be done on the hand-held device and look for an intuitive user interface. This can be key for companies that often have summer workers or a high churn rate in warehouse employees.

6. Too much focus on supporting current processes – even if they are inefficient

There is a tendency to have a requirement sounding like the following: “We should at least be able to do what we do today”. While this might sound fair, it also gives a wrong perspective in the design of the WMS solution. It results in a focus on whether the new system can cover the existing functionality rather than analysing the current processes and how they can be redesigned for the better with the new WMS.

Therefore, we recommend that you – in your perspective and communication – move towards new and more effective warehouse operations with room for adjustment and redefinition of the process landscape for the warehouse.

7. Wrong scope due to missing insight on current processes and needs

Before you create a great scope, business case and project plan, you need to clarify which current processes and key areas need improvement. Nonetheless, we often see that the WMS comes into the picture out of necessity and not due to a clear business case where time and costs can be reduced. This leads to an unclear scope, where the goal is to implement a WMS with limited consideration of what the expected outcome is. Often, the outcome of such a WMS project is a questionable return of investment and a big challenge in terms of the change management efforts due to a lack of focus on operations and expected benefits.

Therefore, we recommend that you spend time assessing your current warehouse operations to find the important focus areas and be on point about what business impact (KPI) needs to be improved as well as behavioural impact.

8. Neglection of training efforts

Training is key to a successful WMS implementation. However, it is also a challenge to many companies. When you implement a new WMS, it introduces new master data such as packaging data, units per pallet, ABC bins, bins for allergens etc. This requires a lot of preparation to properly train the users of the system. Often, in WMS projects, another parameter is that training is not done with the correct devices but with simulation screens on a PC. Therefore, on top of the general pitfalls, where training is underestimated, you also have the complexity of new devices, and you need to prepare a lot in a testing/educational environment.

We have no easy answer to this pitfall other than the need to prioritise it. The investment is worthwhile compared to going live with a system where users are not confident in the use of the WMS.

We hope this blog post has sparked some ideas for your next WMS project so that you can make sure to mitigate risks and enhance your possibilities for a flawless WMS project!

Don’t hesitate to contact us.