Moving the sustainability agenda from strategy to operational action

7 September 2022

Translating sustainability strategies into real operational change

Many organisations have started formulating sustainability strategies in response to increasing sustainability demands from customers, business partners and regulatory institutions, and some organisations have even committed to ambitious sustainability goals. But even with the best of intentions in place, the actual implementation is the crucial focal point when effectively translating sustainable ambitions into operational action.

Today, many organisations are continuously trying to wrap their heads around upcoming sustainability-related regulation and how changing customer demands offer them new market opportunities. At the same time, they need to make sure that their sustainability ambitions can be translated effectively into operations. To succeed in this, you need to find answers to how both regulatory implications and changes in customer demands will impact each team’s daily way of working and change their conversations, prioritisation and their daily decision-making – so you can transform strategy into tangible action.

Regulatory demand for documentation

From the regulatory side, we see increased pressure for large organisations to become more transparent in how they implement their strategic sustainability ambitions into their own operations, as well as throughout their entire value chain.

For large EU-based corporations, clear documentation for sustainability / ESG performance will become mandatory for organisations’ operations as well as suppliers when the European Corporate Sustainability Reporting Directive (CSRD) comes into effect on 1 January 2024 (for the financial year 2023) – as well as the Corporate Sustainability Due Diligence Directive (CSDD), which is expected to be implemented in 2025.

Several countries have already implemented similar national laws, putting increased demands on organisations to disclose how they actually operationalise their sustainability strategy.

The importance of operationalising your sustainable strategy

Your organisation might already have formulated an ambition of becoming carbon neutral or committed to SBTI’s goal of net-zero. But what does “Lars” in the purchasing department do differently when he comes into the office Tuesday morning? And how does “Louise” prioritise her many tasks differently before wrapping up her week on Friday?

Maybe you don’t know every aspect that needs to change in your operations now, but they are important. Your sustainability strategy is important and so is its operationalisation.

Working with sustainability strategies and operational implications, we identified two key aspects for operationalising a sustainable strategy effectively:

- Your sustainability strategy needs to become an integral part of the way you work – not an extra add-on

- You can benefit from enriching and complementing existing best-practice to operationalise your strategy

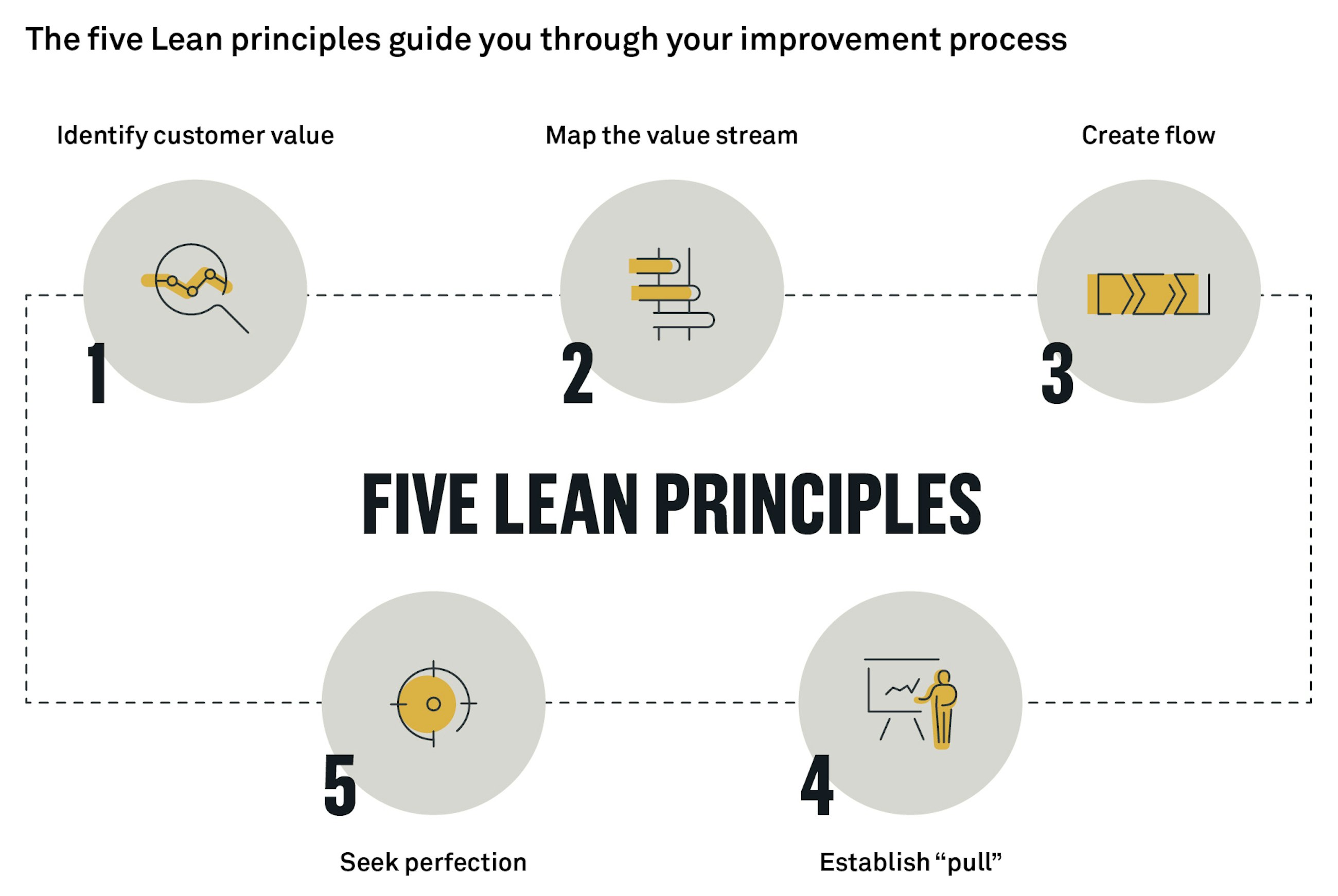

If you enrich and complement existing best practices in operations with sustainability goals, you gain the benefits of building on well-proven methods and tools to operationalise strategic sustainability ambitions. For instance, you can enrich and re-use selected Lean principles and tools to operationalise sustainability ambitions.

Creating customer value and using resources effectively

Let us explain this using a real-life example from one of our colleague's last vacation to Berlin.

When checking in at the little hotel in Kreuzberg, the friendly receptionist asked her if she would prefer a free welcome drink instead of daily cleaning. As she was only staying for two nights, she happily accepted the offer of a delicious gin and tonic.

So what happened? The hotel’s overall strategy is unknown, but for the sake of the example, a fitting strategic ambition could have been as follows: We want the happiest customers with the lowest emission footprint in the industry – while increasing our operating margin.

With this strategic ambition in mind, the hotel actually took the first of the five Lean principles, “identify customer value” as its starting point. When just staying for a few nights, some customers prefer a welcome drink to having their room cleaned. Meanwhile the hotel focuses on happy customers – the core of their strategy – whilst saving water, chemicals, and staff for cleaning rooms. In this way, the hotel manged to integrate its sustainability ambitions into its core strategy.

However, to allow each guest to choose their preference on arrival, without creating a more expensive setup, the hotel needs to adjust their operating model so it accounts for variations in the guest’s demand, whilst still delivering high quality.

Let’s zoom in on the changes in the underlying operating model.

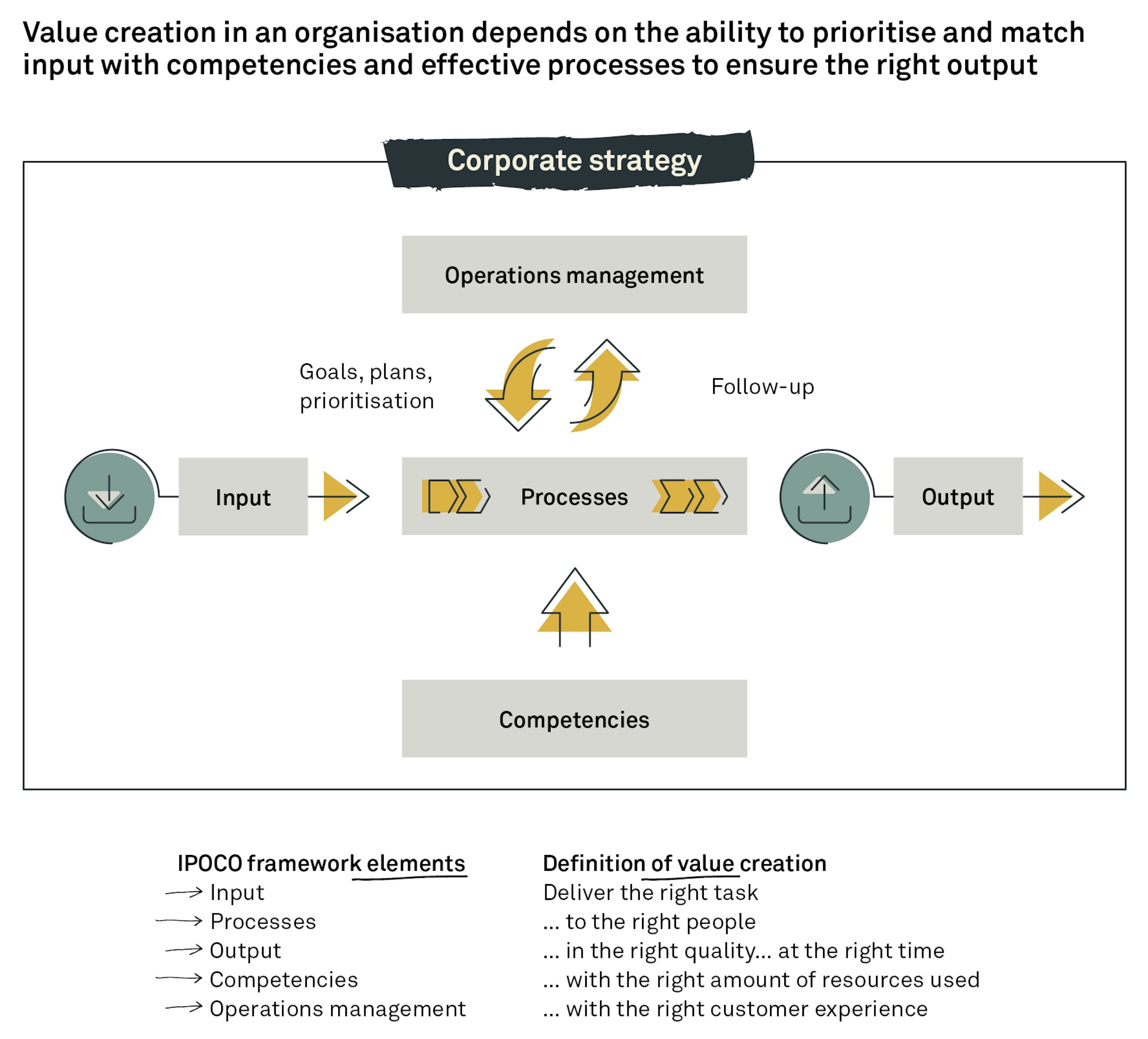

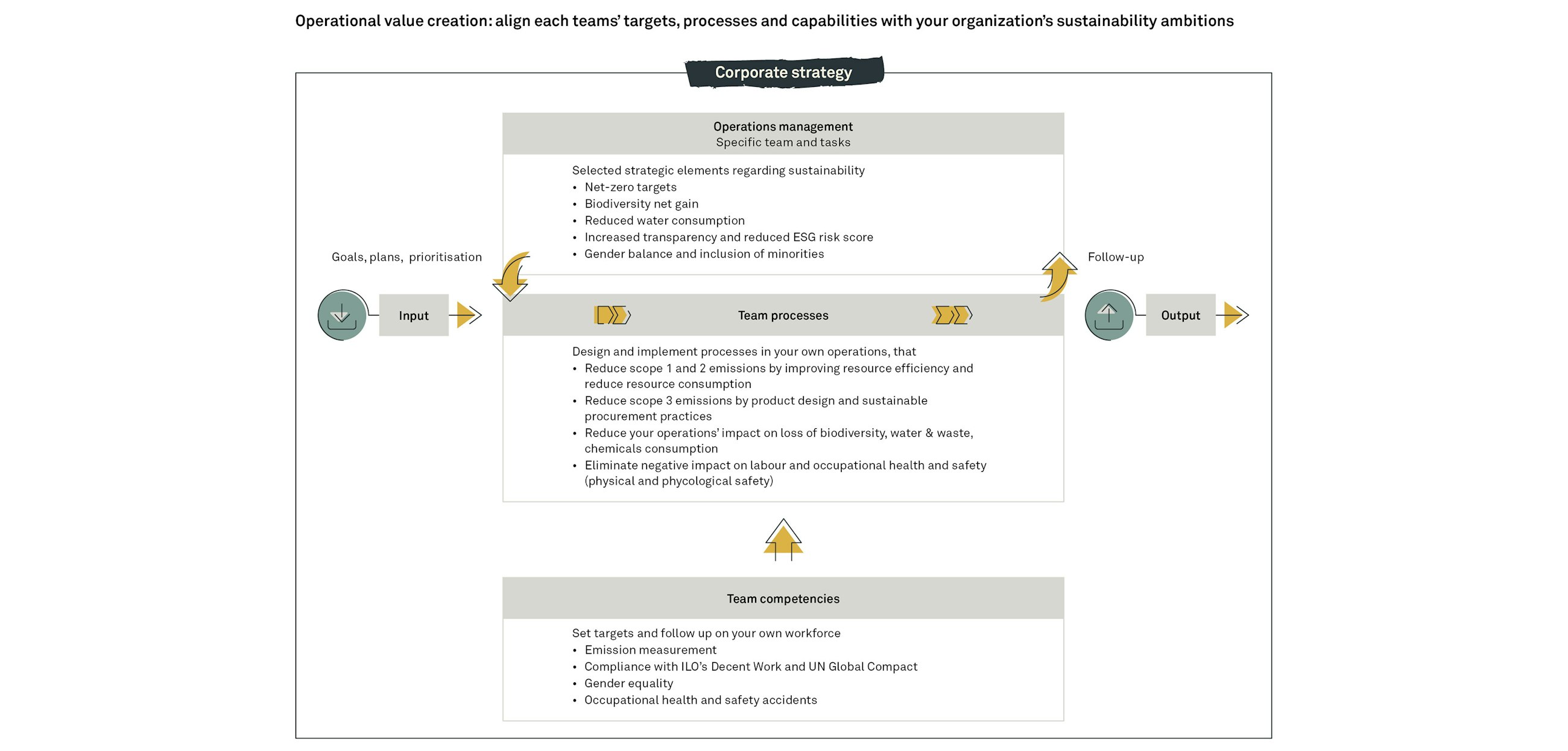

To clearly understand all relevant dimensions of the operational implications of this example, we will use the IPOCO framework. IPOCO stands for Input, Process, Output, Competences and Operations management. The framework enables you to translate your strategic ambitions into operational change by aligning daily operational decision-making and prioritisation with your organisation’s strategic targets.

In the Operations management element of IPOCO, you create the connection between the strategic ambitions and daily operational decision-making. Setting clear goals (e.g., team KPIs) allows you to break down the strategic ambitions to operational targets. This way the team goals reflect how the team can best contribute to the overall strategy and ensure that the day-to-day prioritisation is aligned with strategic ambition. Daily or weekly follow-ups, combined with leading indicators, allow the team to make decisions that are directly aligned with the organisation’s overall strategy. In this example, the team goals could, for instance, consist of three elements:

- Improve customer satisfaction

- Increase operating margin (e.g., cost effectiveness or hours spent)

- Reduce the environmental footprint per guest (incl. CO2 footprint, cleaning material and water consumption)

This way the team goals account for business success and environmental performance. To be able to ensure happy customers, the hotel must adjust daily staffing based on the daily choices of guests. A prediction can help the hotel to roughly plan the percentage of customers who prefer a drink over cleaning (input), but they need to adjust capacity daily to account for actual daily demand. To be able to effectively respond to the variation in the guests’ choices, the team’s competences should be expanded so that several employees can both take the cleaning role and make delicious drinks.

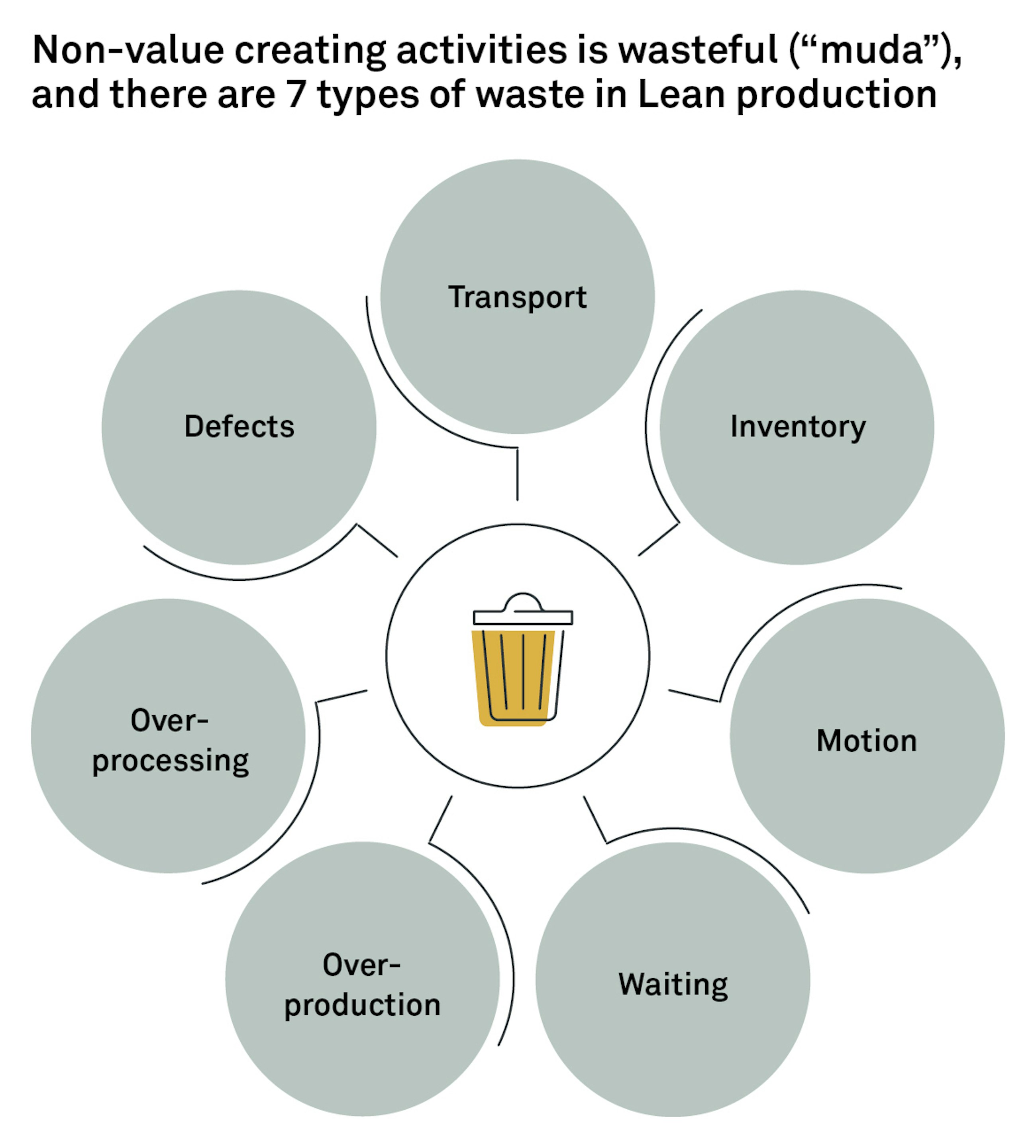

The process around registering the guests’ preferences can be optimised by letting each guest check in via a terminal, where they can choose between cleaning and a drink whilst checking in themselves. When aiming to improve process efficiency, it can also be useful to revisit the 7 types of waste that are part of the Lean toolbox. In this example, the hotel has removed the waste related to “over-processing”, as they stopped spending time cleaning guest rooms for guests who don’t value this service. To ensure the right output quality, the guest can be asked to rate their experience during check-out.

In this example, the hotel manged to integrate its sustainability ambitions into its overall strategy and re-used existing tools and frameworks for operationalisation. The hotel managed to reduce its guest’s environmental footprint whilst also improving its operating margin. However, be aware that you cannot always make it a win-win situation when including sustainability ambitions into operations. When operationalising your sustainability strategy, you can be curious to identify possible cost savings, but sometimes, operationalising sustainability aspects are a necessary investment to stay competitive in the long-term.

Making sustainability ambitions operational

The example above is quite simplistic, and probably your operations are somewhat more complex than that. However, the logic of IPOCO stands for every team that transforms input into output. Below, we provide some additional inspiration on how you can operationalise your sustainability strategy in everyday operations using the IPOCO framework.

How to get started

Even if the example of the hotel experience is very simplistic, it illustrates how you can operationalise strategic ambitions by building onto existing best practices. Often, it is not that obvious how you effectively integrate sustainability ambitions into your core business strategy. It requires a mix of innovative solutions, an adjusted operating model, and often also new competencies. But once you start to translate your strategic sustainability ambitions into operational action, you can make use of existing, well-proven tools and best practices.

The point is, that you need to turn your strategic ambitions into real, sustainable impact to make a change.

And to succeed in that, every team and employee in your organisation – including Lars and Louise – need to know how to act and prioritise amongst all their many daily tasks.

We suggest five practical steps to ensure real impact when translating sustainable strategy to operations:

- Define your organisation’s strategic ambition and target for sustainability performance

- Break down the target into tangible functional, divisional and team goals – maybe even individual goals if it makes sense for your organisation

- Redefine the operating model to reach targets and ensure new roles and behaviours are developed – ensuring that Lars and Louise know how to act differently on a day-to-day basis

- Continuously develop solution initiatives and test pilots – identify your own gin & tonic – and create customer value

- Scale operational implementation based on pilot results and learnings