Article

A business imperative for future-fit supply chain management

Published

5 May 2024

Business leaders must embrace a new and more holistic approach to supply chain management to drive meaningful change and create value for their organisations, their value chains and society as a whole.

This article delves into the critical role of supply chain sustainability in modern business, emphasising its importance for environmental stewardship, social responsibility and economic viability as well as the challenges companies face in implementing it. In the first part, we explain the concept and significance of sustainable supply chain management, while in the second part, we zoom in on a key part of environmental sustainability, namely how to approach emissions reductions.

What is supply chain sustainability?

In the rapidly evolving landscape of global trade, supply chain professionals have the power and responsibility to lead a substantial change in how businesses operate. The traditional focus on cost, reliability and efficiency in supply chain management is no longer sufficient. We need to advance towards a more sustainable existence for our organisations and the world at large. Here, our supply chain decisions must be rooted in a holistic value chain approach and reflect a firm commitment to the triple bottom line: people, planet and profit.

Although recent years have seen an emphasis on the environmental aspect of supply chain management, true supply chain sustainability encompasses the integration of environmental, social “people” and economic “profit” considerations into the management of supply chains. This also includes adherence to sound governance practices. In essence, sustainable supply chain management minimises the negative impacts and maximises the positive benefits of supply chain activities on the triple bottom line and within the planetary boundaries.

Advocating for supply chain sustainability is not only an ethical obligation but also a strategic opportunity to create value, innovation and resilience in our businesses and society. This endeavour requires a paradigm shift – a systemic and holistic approach that considers the interdependencies along the entire value chain and life cycle of products.

Supply chain sustainability matters now more than ever

“Some years ago, it was a competitive advantage, but now it’s a minimum requirement if we want to remain relevant in the market.”

– Team lead at a global pharmaceutical company

In the 2024 Implement Consulting Group survey on supply chain sustainability, more than 50% of respondents say that supply chain sustainability is business critical for them now or that they are already falling behind. Living the company values, pressure from customers and regulatory compliance are the top three drivers for many companies to implement sustainable supply chain practices, followed by pressure from shareholders and creating revenue opportunities. Companies see sustainability as an opportunity for cost savings, enhanced collaboration, innovation and market differentiation.

In summary, we see three main reasons for companies to engage in supply chain sustainability:

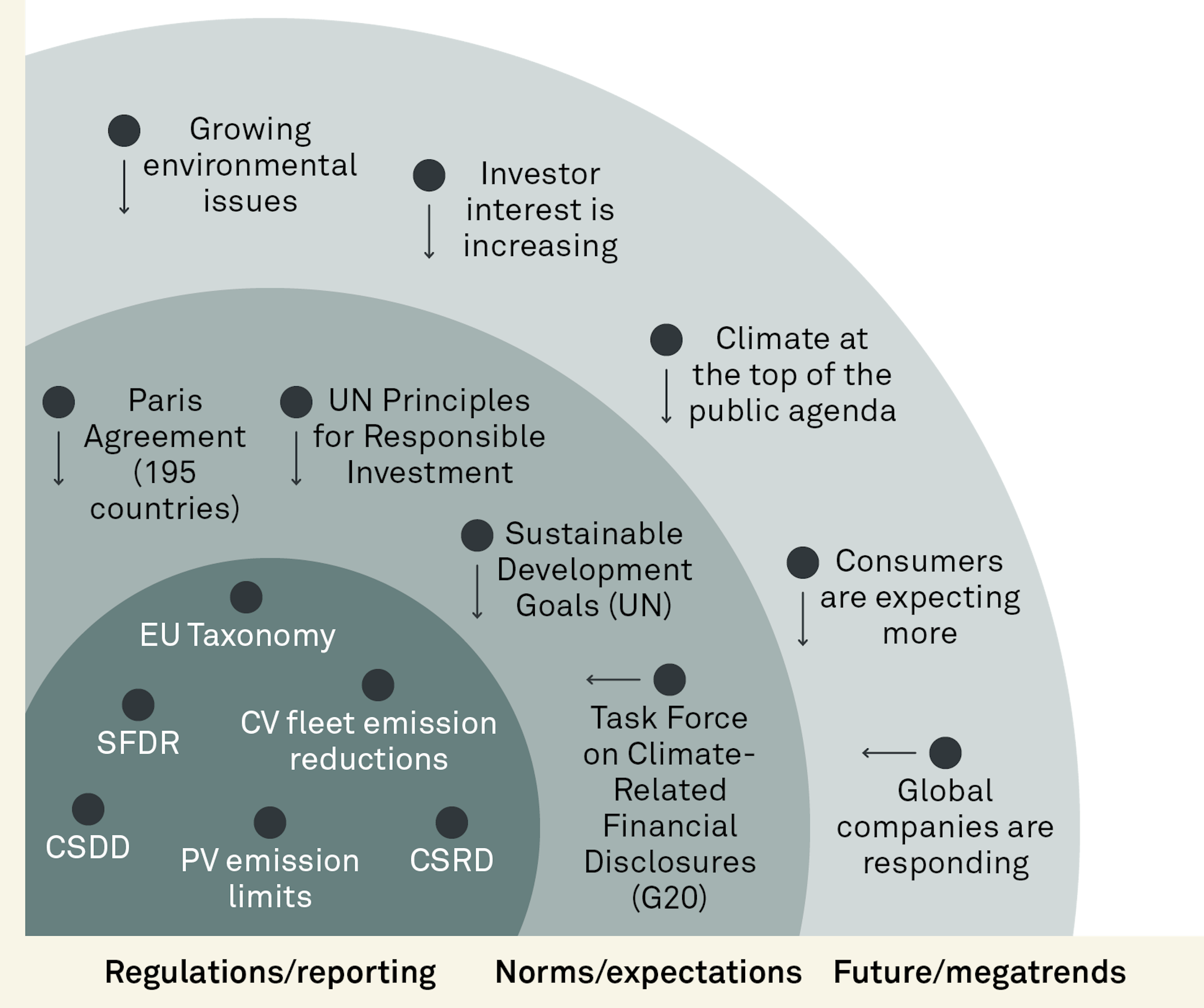

- First, it is a response to the growing expectations and demands of internal and external stakeholders, such as customers, investors, regulators, employees and communities, who increasingly value the social and environmental performance of businesses, not just their financial results. In the past few years, we have seen more and more policy initiatives and legal regulations being put into place, such as the European Green Deal, which includes directives and regulations, as well as measures such as the Corporate Sustainability Reporting Directive (CSRD) and the Carbon Border Adjustment Mechanism (CBAM), which have a direct impact on supply chain flows into the EU. Companies that fail to implement sustainable practices face the risk of regulatory fines and legal action due to non-compliance, loss of brand reputation and customer trust and reduced attractiveness to talent and investors.

Regulatory pressure for supply chain sustainability (illustrative)

- Second, supply chain sustainability is a way to mitigate risk and reduce costs, ultimately leading to increased resilience and profitability. According to the 2022 report by the World Economic Forum , 8 out of the top 10 perceived global risks are related to environmental and societal issues, such as climate action failure, extreme weather, biodiversity loss, livelihood crises and natural resource crises. These risks pose significant threats to the continuity, quality and security of supply chains and to the health and safety of workers and communities. By adopting sustainable practices, companies can avoid or minimise the negative impact of these risks and potentially save money and enhance their reputation in the process. Research, such as a study by Harvard Business Review, confirms that there is a positive relationship between companies prioritising sustainability and their financial performance in the long run.

- Third, supply chain sustainability can be a powerful catalyst for innovation and differentiation, leading to new value creation, market access and increased customer loyalty. Illustrating this trend, Siemens Gamesa recently unveiled the GreenerTower, a pioneering construction using lower embodied carbon steel. The GreenerTower ensures a CO2 reduction of ~60% compared to conventional steel. With the majority of emissions from a traditional wind turbine coming from the steel in the tower, Siemens Gamesa’s alternative makes a big difference for customers committed to decarbonising their value chains and society. With that, it creates an appealing new offering in the market, demonstrating how sustainability can drive innovation and differentiation.

Barriers to starting the sustainability transformation

“It’s still “costly” to improve. We need to find a win-win.”

– Director of a Nordic construction company

While the need for sustainability is receiving public attention and offering genuine opportunities for companies, it is still challenging to get started. In the 2024 Implement Consulting Group survey on supply chain sustainability, business leaders highlighted several key challenges to achieving sustainability in the supply chain:

- Cost-effective solutions: companies find it challenging to present a compelling business case for sustainability in the supply chain due to increased costs.

- Customer willingness to pay: although a study by Implement Consulting Group reveals that consumers report a willingness to pay an additional 5-20% for sustainable products, the reality is that they typically spend only 5-10% more. This discrepancy leads to scepticism among companies about recovering investments and increased operating expenses through higher product pricing.

- Supplier capabilities: the sustainability journey is hampered by the limited understanding and ability of many suppliers to provide the necessary data and engage in joint sustainability efforts.

- Supply chain visibility: the complexity of tracking and managing data and documentation makes supply chain transparency a significant obstacle.

- Internal capabilities: organisations are often unprepared and lack the expertise and knowledge required to drive the emerging field of supply chain sustainability.

With the range and breadth of barriers that companies need to work through, having a clear vision and a stepwise approach aligned with strategic goals becomes critical. Addressing data availability and quality, supplier collaboration, supply chain transparency and internal readiness can be orchestrated with more or less coordination across workstreams. None of these are trivial tasks, so being able to strike a balance between long-term aspirations and effectively responding to current needs becomes key.

Start your transformation journey today

In our experience, companies looking to make their supply chains more sustainable have very different starting points. The understanding of what the concept even means usually differs quite a lot within the company and across its critical value chain partners, so defining a stepwise approach with clear objectives and appropriate levels of stakeholder communication along the way is key to success. So, where do you start? Well, unless you are a start-up on the verge of establishing a supply network from scratch, it is fairly rare that the conversation starts top-down with the corporate strategy, even if that is the ideal scenario. Much more often, there are urgent issues or commercial drivers for reviewing a certain part of the supply chain and looking for improvements that will improve sustainability impacts and reduce costs, which in the process compels a business to check against strategic priorities. The approach becomes less linear, perhaps more iterative, and the outcome less long term, but every time the conversation takes place is an opportunity to do better and challenge business as usual. When working with clients, we always bring the bigger perspective and vision, but we start with where they are.

High-level approach to creating sustainable supply chains

- Define your level of ambition: the strategic aspiration – for some, meeting upcoming compliance requirements can be a challenge; for others, nothing less than industry leadership makes sense.

- Understand your value chain: map flows and interdependencies in detail, and find out where you have heavy processing and vulnerable supply structures.

- Decide where to focus: a double materiality assessment that you might need to do anyway for compliance purposes can help guide this, and your risks and opportunities will depend on your sector, product and market position. A helpful guiding question might be: what parts of your value chain are you most reliant on to drive value in your product and service offering?

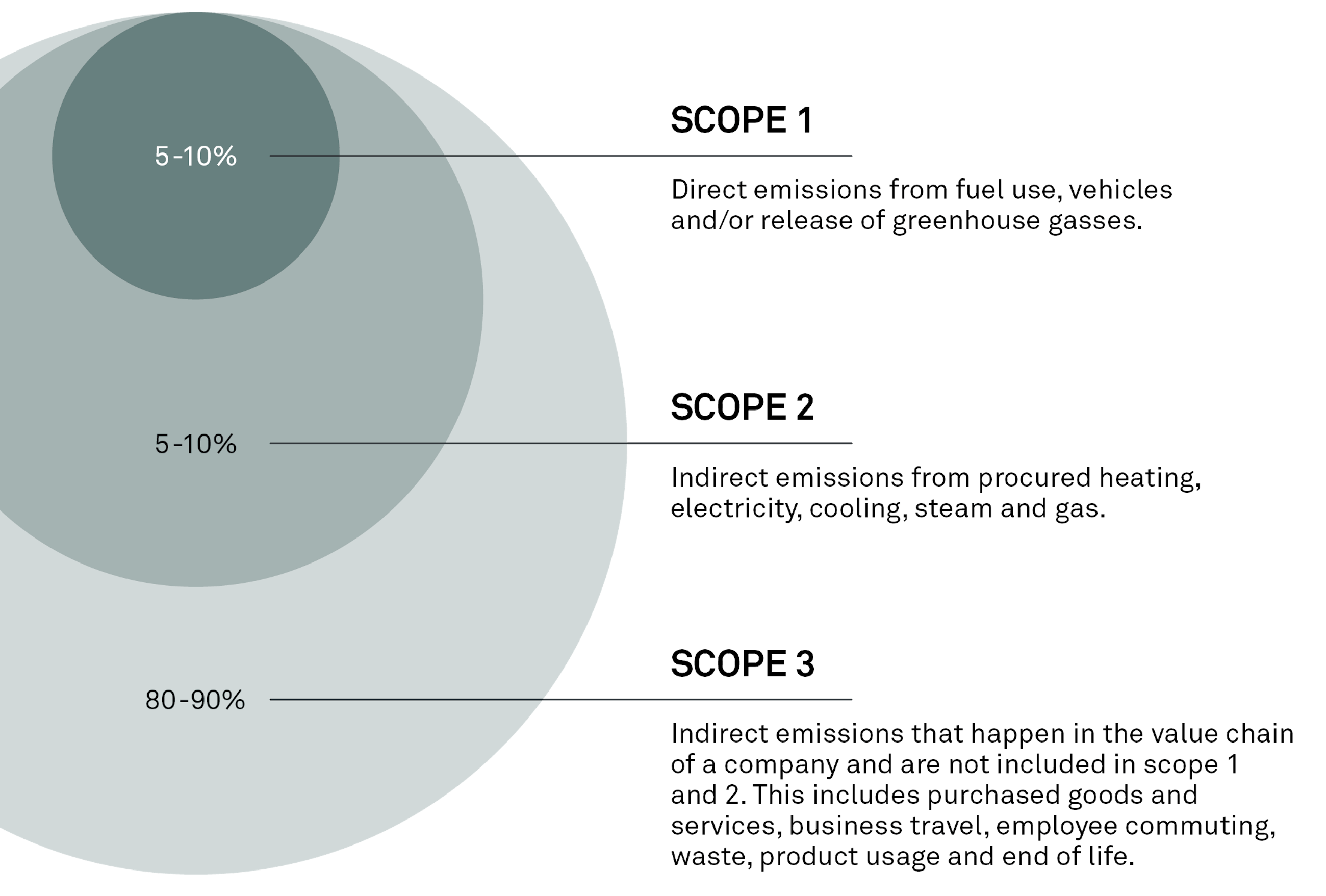

- Develop your baseline and create transparency: for decarbonisation, this means creating a greenhouse gas inventory across all scopes – scope 1, 2 and 3 as guided by the Greenhouse Gas Protocol.

- Set targets and plan how to deliver: this could be net-zero and science-based targets that compel you to dramatically reduce emissions from your operations and value chain in the short and long term, along with a decarbonisation roadmap that identifies the key levers to achieve the targets. Establish priority workstreams, and develop a plan for each.

- Mobilise resources: the resources here are financial, expertise, manpower, processes and governance. Define the organisation, and create the mandate to deliver on the company’s decarbonisation goals. Secure the investment required for CAPEX, specialist expertise, dedicated teams, data management tools and changes to processes and KPIs.

- Execute: ensure strong project management across all workstreams and accountability structures that make progress visible to the right stakeholders. Prioritise communication and engagement internally and externally to build momentum and unlock the energy of employees and peers working to solve the same challenges you face.

- Monitor and track performance against targets: embed decarbonisation KPIs into existing reporting structures throughout the organisation and with key value chain partners, with the same rigour as tracking financial performance.

- Continuously improve: recognise that working with sustainability means that you are never done. You will face challenges, opportunities and inspiration in every part of your journey. Aim for an agile structure that allows you to easily adapt your approach and adopt new learning.

Many businesses have already committed to net-zero emissions across their value chains by 2050. If they have committed to recognised standards, such as the Science Based Targets initiative (SBTi), they will also have much shorter-term targets, most aggressively for their scope 1 and 2 emissions from their own operations. Scope 3, however, is a very different beast, and so the approaches vary tremendously. However, there are significant opportunities to synergise and leverage learnings from your own company’s decarbonisation journey to start tackling scope 3 emissions in your supply chain. After all, one company’s scope 3 emissions are another company’s scope 1 and 2 emissions. If everyone “only” addressed their own scope 1 and 2 emissions, the concept of scope 3 might not even exist.

Overview of emissions scope based on the GHG Protocol 2022

It makes sense to start with the activities that you directly control, and there are many learnings that can be leveraged when opening the door to scope 3. Nevertheless, it is crucial to recognise that, on average, industrial firms tend to have a substantial 90% of their emissions fall within scope 3, with only 10% attributed to scope 1 and 2. We have outlined a hands-on approach and are further exploring the approach to reducing scope 1, 2 and 3 emissions in a separate article.

Conclusion: supply chain sustainability has become a business imperative

In conclusion, supply chain sustainability is no longer a fringe concept or secondary concern; it has become a business imperative. The journey to a sustainable supply chain comes with challenges such as cost constraints, consumer expectations, supplier engagement and the need for enhanced transparency and internal capabilities. Yet, it is a path that companies must navigate to meet the pressing demands of stakeholders, mitigate risk, reduce costs and foster innovation. The transformation towards sustainable supply chains calls for a strategic, holistic approach that aligns with a company’s core values and leverages every opportunity for progress.

As we have discussed, this transformation is not just about compliance with emerging regulations or short-term gains, but about the long-term viability and ethical responsibility of businesses. Companies that embark on this journey will find themselves not only adapting to a changing world but leading the way to a more resilient, equitable and environmentally conscious future. It is imperative for businesses to start their transformation journey today, with a clear vision, a stepwise approach and a commitment to continuous improvement. The choices made now will define the legacy of today’s business leaders and the health of our planet for generations to come.

Curious for more?

Curious about how you can strategise towards a more sustainable supply chain? Reach out to our experts.

Related0 4

Case

Read more

Leading global investment bank

How can sustainable choices lead to higher returns for investors?Case

Read more

A global energy company

How does a leading energy player leverage sustainability to win more business?Case

Read more

Leading private equity firm

How can private equity use sustainability as a value creation lever across its portfolio?Case

Read more