A road map to an effective shelf life process in your supply chain

3 September 2019

Many companies experience challenges in planning and executing their supply chain with respect to shelf life. Therefore, they seek to find a solution that can reduce the risk of scrap while securing high delivery performance.

Often, companies start by looking for complex IT solutions that typically require high development costs and a long implementation time instead of focusing first on having the fundamentals in place in their daily processes. We believe that the correct approach to tackle shelf life challenges is to proceed through incremental phases with focus on fast value realisation.

So, what is shelf life planning and execution?

We use a combination of two definitions to describe shelf life planning and execution:

- Shelf life planning is the management of trade-offs between risk of scrapping products, caused by too large orders, and thus excess inventory, and risk of lost sales due to unavailability of products on the shelves.

- Shelf life execution is about producing the right quantity at the right time, executing the flow of products in the right sequence and dealing with customers in a proactive manner.

In many industries, companies are subject to the concept of product perishability: after some time, products are no longer allowed to be sold to customers due to deterioration of quality, safety reasons etc. You find the perhaps most well-known example in the food industry, where products have a so-called “best-before date” or a “use-by date” indicating the date before which the product’s flavour and/or quality is best, or when it can no longer be sold to the consumer (in some cases, the date indicates both).

However, many other industries such as pharmaceuticals and chemicals are also affected by the perishable nature of their products and the subsequent increasing complexity of managing this challenge.

The shelf life of products can have a large effect on how we design the production and distribution network. For products with low shelf life flexibility (meaning little time between production and the last sellable data), higher lead times due to centralization can pose a challenge. Therefore, decentralisation of production and warehouse might be the preferred option to ensure fast response. On the other hand, centralisation can also lead to lower levels of total stock and having higher degrees of scrap stock turnover and can result in a reduced level of scrap.

Different customers request different shelf life

It is important that you make a distinction between the “best-before date” or “use-by date” that the consumers see when they buy a product in a store and the “minimum required shelf life” demanded by B2B customers in the supply chain.

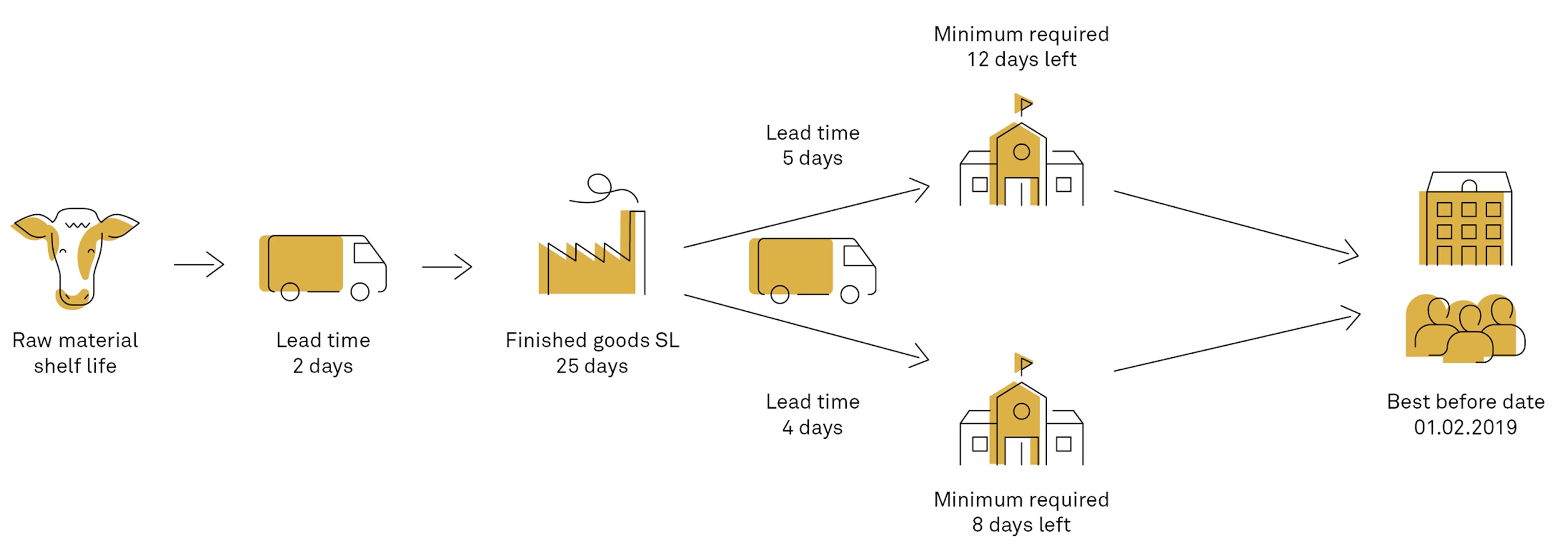

A key concept to understand in differentiated shelf life planning and execution is the minimum required shelf life. It is what a customer (B2B) demands for a product, when it reaches their inventory. When produced, a product might have 25 days of shelf life left before it reaches the “best-before date” – but a retailer selling the product might demand a minimum of 15 days to have enough time to sell the product before it expires.

You will experience an increasing complexity in your shelf life planning, when different customers (internal or external) demand different shelf life.

So why do customers demand different shelf life? The reasons can be many. Some examples are:

- Logistics: In many cases, the customers require different shelf life due to different logistics setup in their supply chains. This can be different lead times, storage and transportation conditions etc.

- Commercial: Often, Sales have a say in the shelf life agreements that are made with each customer.

- Buyer power: Large customers can “bully their way through” to demanding higher minimum remaining shelf life to achieve flexibility in the supply chain and reduce scrap at their end.

- Internal: The different shelf life requirements can also come from internal customers where the different distribution centres have different lead times etc.

How to tackle the differentiated shelf life challenge in five phases

Shelf life planning and execution is about processes as well as IT, but in your solution road map, you should let the process focus come first.

Many companies often start by looking for advanced IT solutions solutions that can manage their shelf life planning and execution process. A better approach is to start by getting the basics in place before moving on to the system side. If you define the “easy wins”, you can create faster impact by reducing yearly scrap value and improving customer delivery performance. So, start out with a minimal viable solution instead of letting your first step being an advanced system solution, which is both costly and takes time to implement.

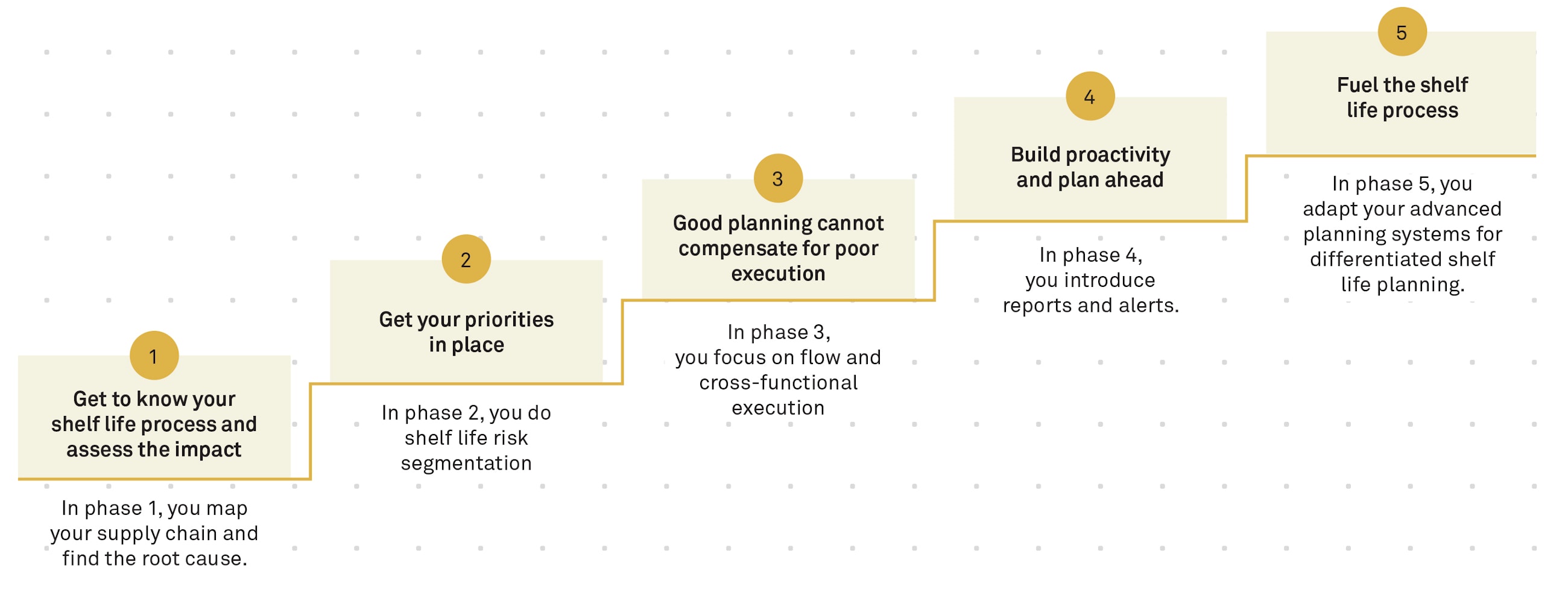

We suggest an approach consisting of five phases. In the first three phases, you focus on the processes, whereas in the last two phases, you focus more on the supporting IT tools. You determine where to start depending on the level of maturity in your shelf life planning and execution process.

1. Get to know your shelf life process and assess the impact

Get to know your customers and the process

Who is responsible for negotiating the shelf life agreements with customers, and how is this done? Where in the supply chain do we see the most scrap and non-deliveries due to shelf life issues? Are the shelf life agreements carved in stone, or is there room for exception handling?

Customers can have different shelf life requirements for several reasons. A large customer can demand higher shelf life due to buyer bargaining power. Some of these customers might, under certain circumstances, accept a lower remaining shelf life than they agreed. But if you do not maintain a continuous customer dialogue, you may overlook this option.

On the other hand, smaller, less important customers should not be allowed a too high remaining shelf life, unless they are willing to pay a higher price for it. The customer gains more flexibility in their supply chain when they have an increased shelf life, and it is therefore reasonable that you address this in your pricing strategy.

You may also discover potential for simplification while investigating the root cause behind the differentiated shelf life setup. Can we streamline the shelf life agreements and the supply footprint to reduce complexity? For instance, you could standardise most of the shelf life agreements and only offer differentiated shelf life for large important customers.

When you investigate existing shelf life requirements, it is crucial that you involve Sales, as they often play a significant role in defining the customer agreements. It is also necessary that you point out the supply chain consequences to Sales of offering differentiated minimum required shelf life to customers. It is all about being able to deliver differentiated shelf life requirements effectively and at a competitive price. Supply chain operations must understand the customer requirements, and Sales must understand how differentiated customer agreements impact and influence the overall supply chain from planning and production to warehouse execution.

Start with an impact case and prioritise the effort for fast results

When you want to enable your business to prioritise and focus, we recommend using a method called an “impact case”. The method is aimed at identifying the potential business impact, and the following areas should be addressed:

- The amount of materials and customers with different shelf life requirements.

- The amount of scrap that is driven by shelf life expiry.

- The number of customer orders not fulfilled due to too low shelf life of available stock.

- The degree of manual activities: firefighting, planning adjustments to forecast and the suggested production orders etc. to avoid shelf life expiry and/or poor customer service (measured in time).

- The number of different shelf life agreements with customers and the pricing strategy.

2. Get your priorities in place and create focus

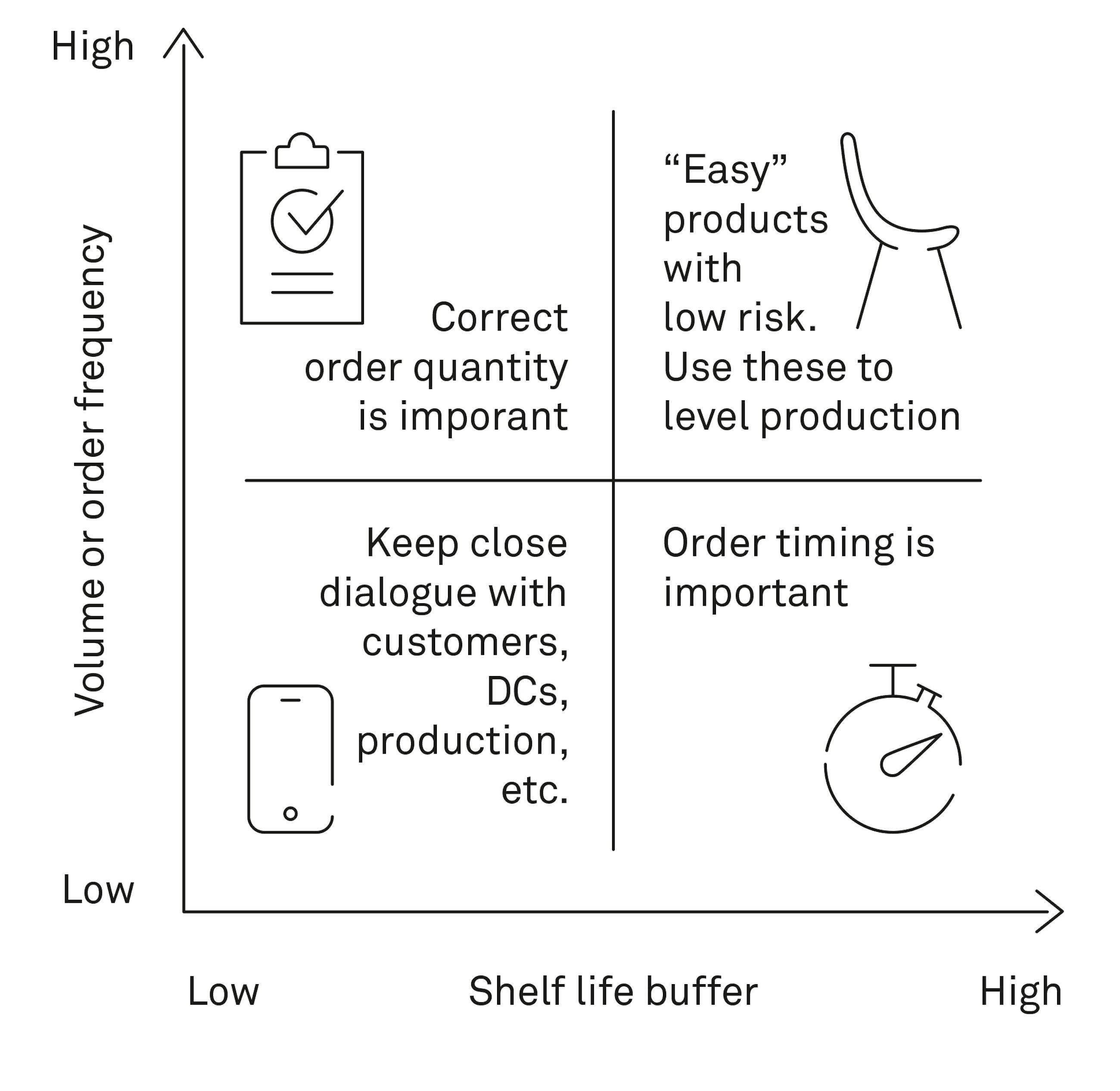

You can help create focus by conducting an analysis of the products at risk. This also ensures proactive attention and dialogue for the daily processes within sales, planning, production, execution etc. When you do the segmentation, you should identify the products where the risk of scrap is the highest. These products can be defined as the products which both have a low shelf life buffer and at the same time a low volume/frequency. A shelf life buffer is the difference between the expiry date (best-before date or use-by date) and the minimum required shelf life.

The identified product groups allow for applying differentiated planning and execution strategies, and thus efforts can be focused on the more challenging products.

You can easily plan products that have a high shelf life buffer and which are characterised by high order frequency and high volume, as the risk of obsolescence is low. You can automate the production planning of these products to some extent. In addition, you can use these as buffer products, which can be produced to stock beforehand to level out production due to the high demand and high shelf life.

For the products that have a high shelf life and low volume (or the other way around), order timing and quantity are of higher importance, and planners should dedicate more effort to these products.

The tricky products are those that are subjected both to low and infrequent demand as well as to a low shelf life buffer. Here, a closer customer dialogue is key to confirm that demand is or will be present for the planned orders. As an alternative, you can apply a make-to-order production strategy, when possible. In addition, you must carry out your planning in close contact with sales, production and warehouse to avoid that batches are scrapped.

It can be a good idea to make an analysis where you take the customer sales perspective into account. This can highlight whether some customer agreements should be renegotiated.

3. Good planning cannot compensate for poor execution

To have an effective end-to-end process for shelf life, it is key that you secure the right flow in the execution processes. Execution is not limited to the warehouse, but also entails quality assurance, sales, intercompany replenishment and production.

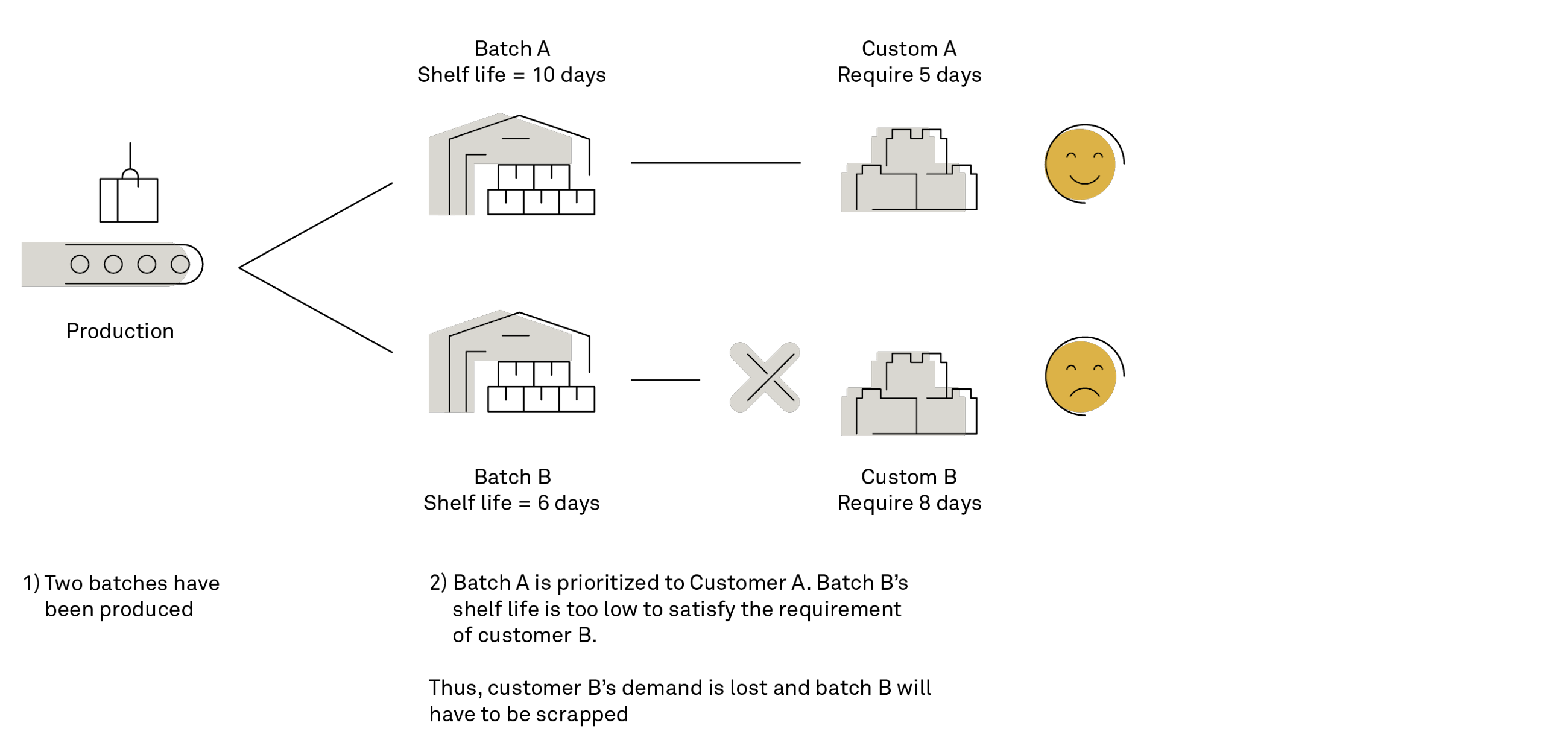

Normally, you should run your warehouse based on the FIFO (first in, first out) principle for the flow of goods. However, this strategy assumes that the goods that have been in the warehouse the longest are also the ones closest to expiry, which is not necessarily the case. Many elements can interfere with the order in which goods are received in the warehouse after production, and so this assumption is no longer true. Especially, if a product can both be produced in-house and sourced from an external vendor or location, then it can be dangerous to rely on FIFO.

Therefore, it is better that you use a FEFO strategy (first expiry, first out) for perishable goods. Here, you pick the batch that is the closest to expiry, but can still meet the customer’s requirement. FEFO requires that you activate batch management in your ERP system, so that batch data (including expiry) can be shared across sites internally and externally in the supply chain. You can also implement a simple standard operating procedure where the batch is checked against a list of the customer requirements to secure that products with too little remaining shelf life are not shipped to customers who require more.

You may experience situations, where no batch on stock is able to meet the shelf life requirement stated in a customer agreement. For some customers, the shelf life agreement might be flexible, and thus Sales can contact the customer to ask if they are willing to accept a batch with less shelf life than the one agreed upon. In these situations, you can offer a discount which can avoid both scrapping the products and losing the customer order.

Quality assurance (QA) is also an important stakeholder to engage for securing the right flow of products. QA is a key process especially in the pharmaceutical industry, and the sequence in which they review and approve batches is just as important as having the right flow in the warehouse. A batch waiting for approval from QA can cause that the batches are shipped to customers in the wrong sequence, potentially resulting in scrap and poor customer service.

Production also needs to adhere to the order quantities and timing made by the planning department. We often see the case where Production increases a production order quantity or changes the sequence of orders to achieve better capacity utilisation. However, this might come with the consequence of scrap or even missed deliveries if too much is produced, or if products are produced too early. Here, you can use a simple planning adherence report to help visualise and tackle such challenges.

It is also key to communicate clearly about demand and shelf life requirements in intercompany replenishment. We see too often that companies only take care of the shelf life requirements of external customers but neglect the internal flow of goods between their own sites. Thus, the shipped batches end up being scrapped as they have too little remaining shelf life when they reach the receiving distribution centre.

4. Build proactivity and plan ahead

When the key departments in your organisation are aligned, and the right focus and flow have been established, the next step will be to start building supporting tools to support the process. These help avoid reactivity and firefighting behaviour.

Some advanced planning systems (APS) support some degree of planning with shelf life expiry (e.g. SAP APO and SAP IBP). However, you can also use simple BI reporting tools or Excel reports, that can be developed to provide an overview of potential scrap scenarios, as well as if there are future customer demands where the shelf life of current stock cannot cover the requirements.

A foundation for this is that your organisation can couple demand elements (forecast and sales orders) with the shelf life requirements. Afterwards, you can compare demand elements and shelf life requirements with stock on hand and then create simple reports to highlight potential risks and give proactive alerts.

Finally, your organisation should also track scrap and delivery issues caused by shelf life in the daily KPIs used in operations.

5. Fuel the shelf life process with advanced planning systems

Some advanced planning systems can plan with shelf life, for example SAP APO and SAP IBP. It can be advantageous to look into how APS solutions can support shelf life planning, if you want to ensure an integrated process where the organisation reacts on the same set of numbers. It is important that you do not focus only on a single process, but consider various aspects of the supply chain planning.

Firstly, for demand planning, a good shelf life planning solution must be able to plan with different customer requirements for both forecast and actual sales order demand.

There are often different shelf life requirements in the intercompany replenishment as well, and you should make sure to account for these too.

Inventory management is highly impacted by shelf life planning. Different lot sizing policies impose different risks for scrapping. Inventory optimisation must not just take holding cost into account but should also seek to reduce the risk of scrap. In addition, time-dependent safety stock planning can add significant complexity to the requirements of MRP heuristics.

For detailed scheduling and production planning, you must consider how scrap and customer requirement information is highlighted in the daily production planning to support an efficient process. In addition, you should consider if/how the solution should support shelf planning on different levels in the bill of materials structure in terms of both semi-finished goods and raw materials.

SAP offers a shelf life planning solution in both their APS offerings: IBP and APO. As a standard, APO has some shelf life planning functionality available but is limited by not supporting shelf life planning with different customer requirements. However, enhancements can be made to APO so it can support differentiated shelf life planning for both DP, SNP and PP/DS. Contrary to APO, standard IBP can plan with differentiated shelf life requirements for both customers and internal logistics flows.

Summary

Managing shelf life planning is a complex subject. First and foremost, it requires the right process and subsequently also the right tools to support the process.

If you do it right, shelf life planning and execution can be a differentiator towards your customers and lead to more efficient operations. As a result, a good shelf life planning process can lead to:

- Better balanced inventory

- Lower scrap from expiry

- Improved supply chain sustainability

- Improved delivery performance

- Lower firefighting in the organisation

- Improved transparency