A post-COVID-19 study

3 September 2020

How global supply chains are affected by and adapting to the effects of COVID-19.

In June 2020, we conducted 34 interviews with supply chain executives across industries with the purpose of creating a better picture of the consequences of COVID-19.

As the focus of this survey is on global supply chains, all the companies that we interviewed have multinational presence in the private sector and are headquartered in Denmark, Sweden and Germany.

Key questions addressed include:

- How has the crisis affected the company supply chain agenda for the coming 1-2 years?

- What are the learnings when hit by a major demand disruption?

The conclusions presented are not meant to be exhaustive and are purely based on the sample of the 34 companies that are interviewed.

Conclusions

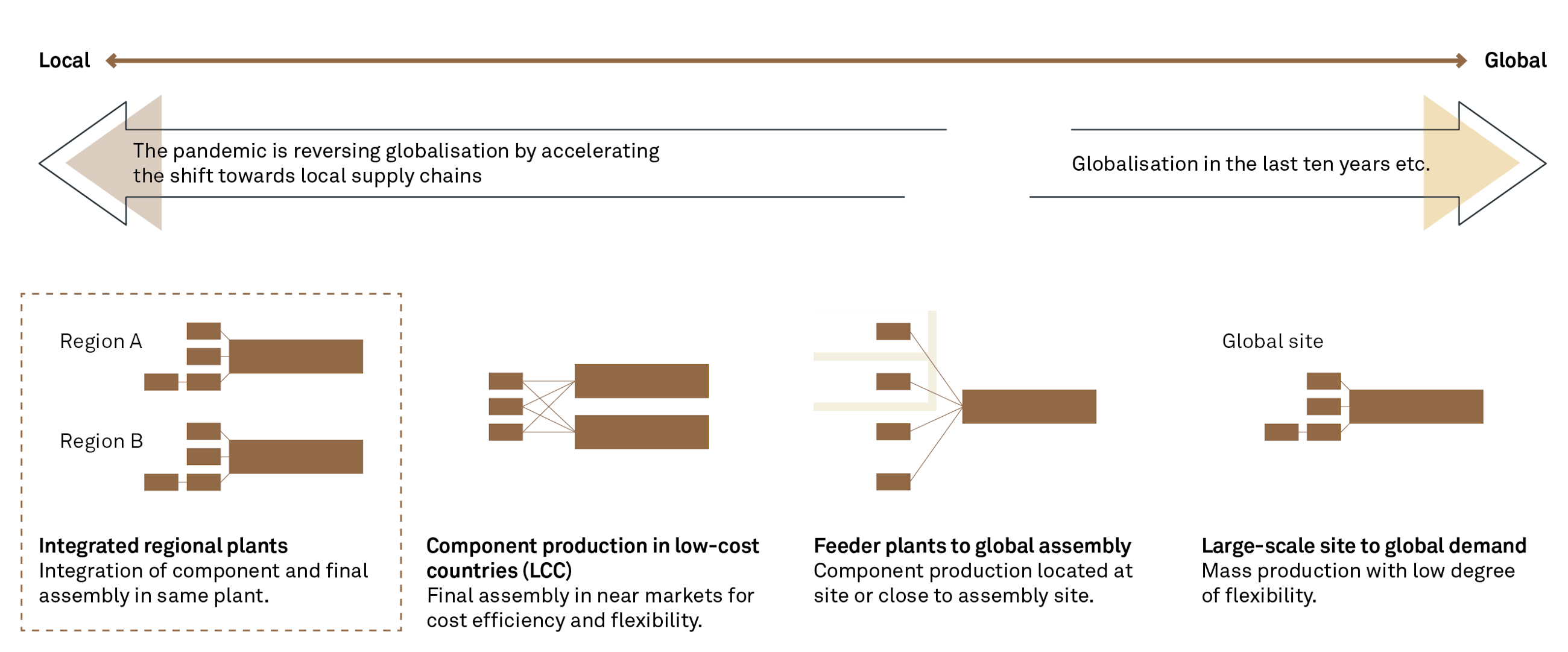

- Back to business: Apart from sourcing strategies, the companies agree that COVID-19 does not change their core supply chain strategy. Most businesses will return to business as usual eventually with the exception of some industries like retail which may take much longer to recover.

- Acceleration in strategic initiatives: Increased urgency for management to accelerate the development on activities that have previously been postponed: redesigning manufacturing and distribution footprint, digitalisation, transparency, automation and omnichannel/e-commerce.

- Supply risk: Companies agree that supply risk diversification in the form of dual and multiple sourcing and regional supply setup can help ensure a more stable supply, while joint investments with suppliers can further strengthen the partnerships.

- Crisis management: There is a general perception that the collaboration across the company’s functions has been strong and effective, and that “corporate theatre” disappeared when the crisis came.

- Operating model: The operating model can be optimised by greater utilisation of virtual collaboration, less travel activity and more frequent touchpoints.

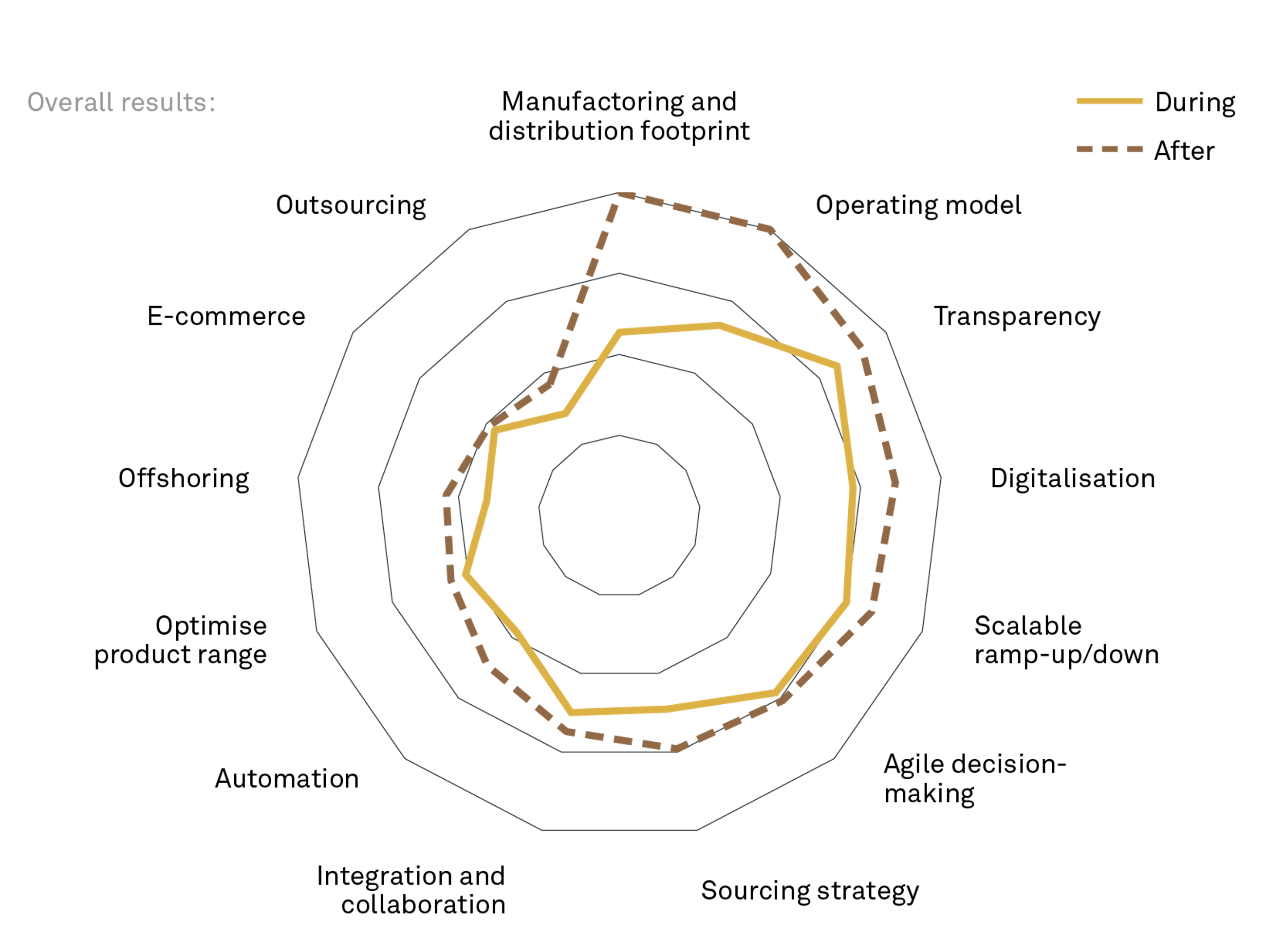

Impact during and after the crisis across key dimensions

Manufacturing and distribution footprint, operating model, transparency and digitalisation are the most important dimensions going forward:

Based on the survey, the most important areas going forward are manufacturing and distribution footprint, operating model, transparency, digitalisation and scalable ramp-up/down.

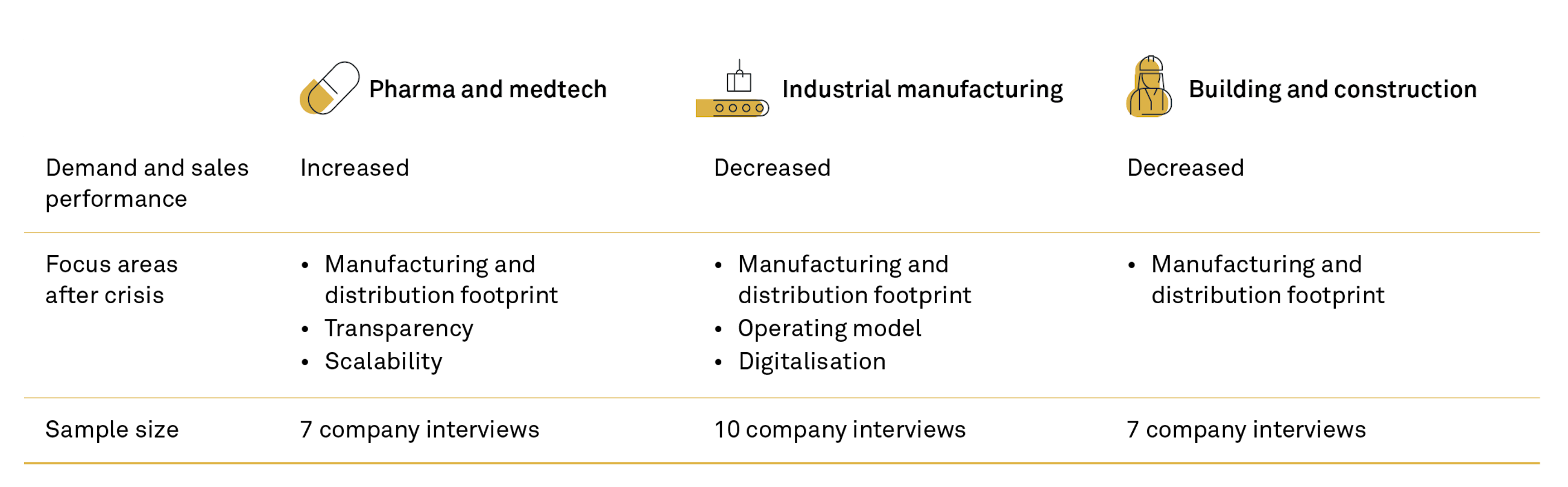

Industry deep-dives

Key findings: