– should you outsource it or keep it in-house?

29 June 2020

A combination of challenges, complexities and resources associated with forecasting motivates many businesses today to consider whether sales forecasting should be kept in-house or outsourced to an external service provider. Here, we will present our view on the question, and which forecast methodologies we believe to fit most current organisations the best.

Why is forecasting important?

In modern supply chains, forecasting plays a key role in operations by driving strategic and planning decisions and enabling critical business activities. Sales forecasting supports financial planning, raw material sourcing as well as production planning and inventory management. Having an accurate sales forecast allows you to achieve a higher delivery performance and service level, leading to higher customer satisfaction. In addition, with accurate forecasts you can enable optimised stock levels, reducing inventory costs and net working capital as well as decreased risk of potential lost sales, thus reduced cost of obsolescence and depreciations.

Nowadays, complex supply chains combined with a fast-changing business environment make forecasting a difficult task. We see businesses facing different challenges when it comes to the sales forecasting process such as lack of quantitative methods or lack of tools to analyse historical trends and calculate statistical baselines. Also, a high number of references can represent a challenge, hindering the manual review as well as the lack of simple methods to include bottom-up input from sales or finance. Forecasting is oftentimes seen as not only complex but also expensive, as organisations utilise valuable time and resources in this process.

The combination of challenges, complexities and resources associated with forecasting motivates many businesses today to consider the following question: Should forecasting be kept in-house or oursourced to third-party providers?

In addition to the question of whether forecasting should take place in-house or outside the company’s boundaries, we also see a recurring question concerning the dilemma between simple vs advanced statistical forecasting methods. Typically, external forecasting providers use advanced algorithms, machine learning and AI methods, but are these in fact bringing real value to the business?

Based on our extensive experience helping organisations design and improve demand planning processes, we have seen that, in most cases, a simple forecasting process managed in-house can outperform fancy advanced algorithms. Simple forecasting consists of combining simple statistical forecasting with market insights in a simple and efficient manner.

Our view on outsourcing forecasting capabilities

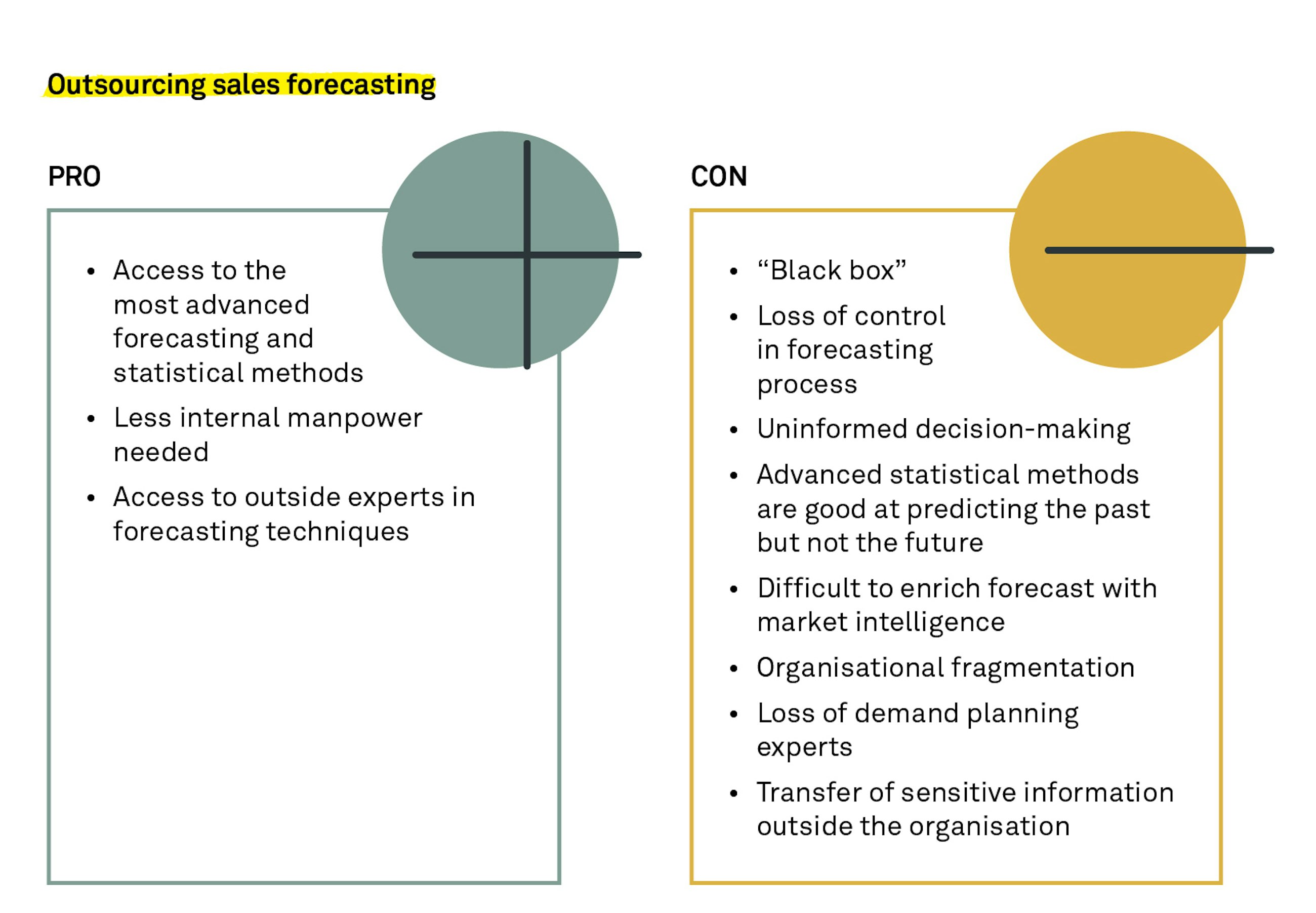

Over the past years, it has become increasingly more popular to outsource non-core business processes to external providers. Organisations opting for outsourcing strategies are often aiming to unlock new technological capabilities, gaining access to new skills and, in many occasions, also cutting costs. Outsourcing sales forecasting is not an exception. By outsourcing the forecasting processes, organisations can free up time of the demand planners and get access to experts in the forecasting field as well as cutting-edge forecasting techniques.

However, there is a downside to outsourcing forecasting. It can be argued that the quality of the forecasting process as a whole may be affected, as the decision-making that takes place in-house will be based on a forecasting result that has been created outside, thus lacking the understanding of how the forecast result has been obtained. In other words, outsourcing forecasting can be seen as a “black box” in which you input historical sales data, and you get an output which represents your future sales, but what happens in-between is completely unknown. Needless to say, “black box” solutions may not always please everyone.

Another consequence of outsourcing forecasting with a “black box” setup is the difficulty of enriching the outsourced forecast baseline. That is, if you are a company that has outsourced the generation of the forecast, you cannot know how much information, such as promotions, capacity constraints, sales strategies etc., has already been incorporated in the calculation of the resulting baseline. Therefore, enriching forecasts with market intelligence can become a big challenge for demand planners and could even worsen the quality of the final forecast.

We all agree that the quality of the forecast is the key driver when considering different forecasting strategies. Generally, companies providing forecasting services use very advanced and quite complex forecasting algorithms. Even though methods like machine learning or advanced statistical models may sound interesting, scientific literature shows that using complex algorithms does not create better results than simple techniques. Advanced forecasting algorithms have shown to be good at predicting the past, but what about the future? Are these methods able to capture the impact in the forecast of future events such as capacity issues, increased sales, promotions or changes in market conditions? The answer is, possibly, no. These types of events are extremely difficult to predict simply by using advanced history-based statistical models. Spyros Makridakis, one of the world’s leading experts on forecasting, argues that complex statistical models fit past data well but do not necessarily predict the future accurately, whereas simple models do not necessarily fit past data well but predict the future better. In short, no advanced statistical models will be accurate because the future, in fact, cannot be written.

READ MORE about simple forecasting in Spyros Makridakis’ book: Forecasting: Methods and Applications.

Keeping supply chain parts and partners working together is already a big challenge in modern organisations, and outsourcing forecasting may not influence in the desired direction. In particular, outsourcing may lead to a loss of control in the forecasting process, which can result in a loss of control in the overall planning processes as well as organisational fragmentation. For example, Marketing, Sales and Finance will no longer talk to Operations in the same way as if a collaborative demand forecasting process would take place in-house. We have seen that when forecasting is outsourced, each organisational area does its own prediction for future sales, that is, Finance will do a value forecast, and Operations will do a volume forecast.

When outsourcing forecasting, there is not only a risk of losing control of business processes, but there is also a risk of losing people with specific knowledge and expertise in demand planning. Outsourcing will naturally lead to a reduction of the number of demand planners needed, which poses a risk of losing valuable knowledge which is not easy to reacquire.

Finally, the last point that needs to be considered here is the willingness to transfer critical information outside the organisation. Security concerns may arise when considering outsourcing forecasting, as some of the inputs required for generating a demand forecast consist of sensitive information such as product launches, future trends or expansion strategies.

Keep it simple – keep it in-house

At this point you may be wondering – why not keep forecasting activities in-house?

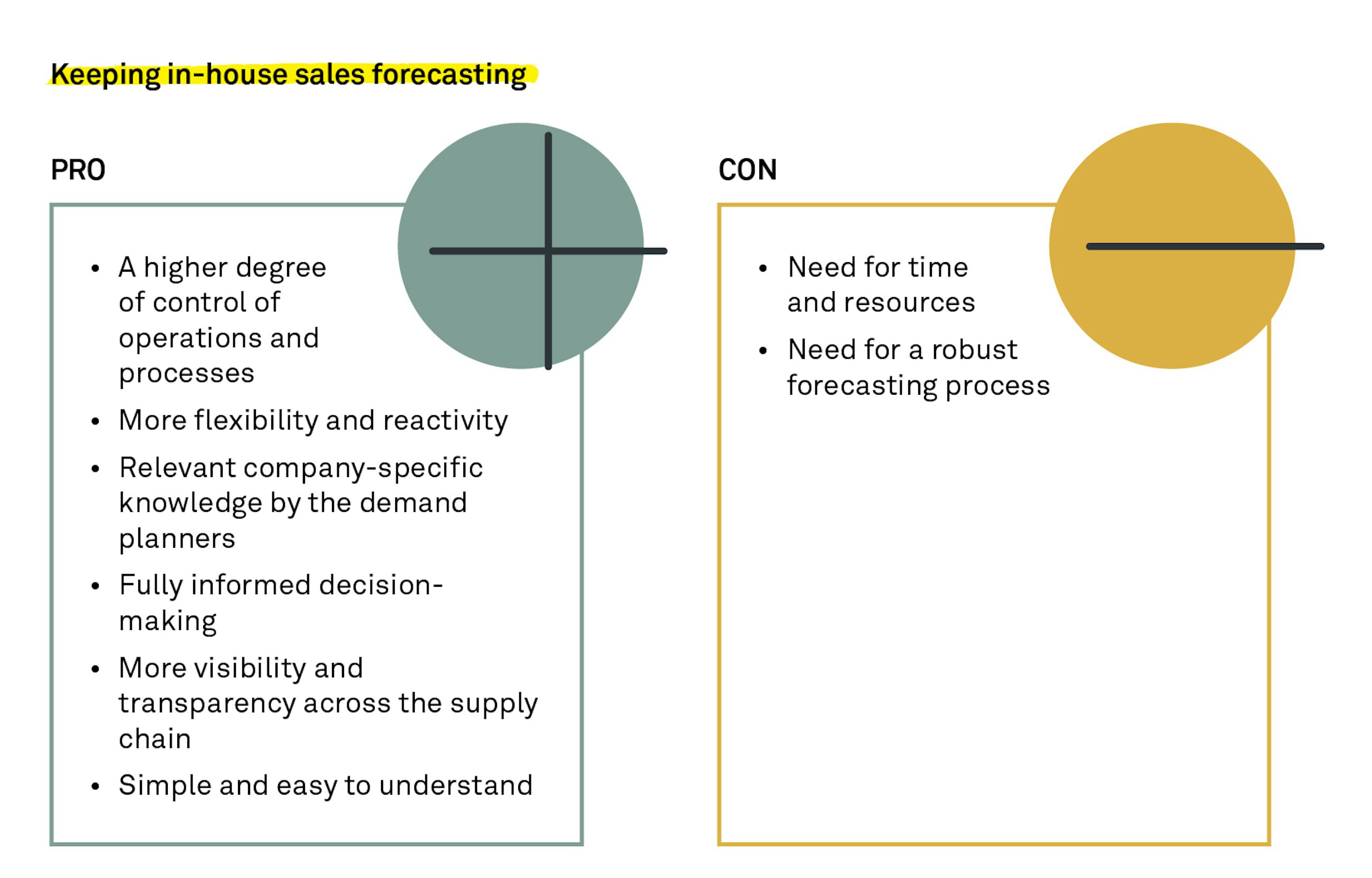

We see many arguments to decide to keep forecasting capabilities within organisations.

First, by maintaining the planning process in-house, not only do we ensure a higher degree of control of operations and processes, but also a higher degree of flexibility and reactivity. Imagine, for example, that your company is facing an unforeseen event such as a supply shortage that will have an important impact on the forecast in the future months. In an outsourcing scenario, you will need to wait until the next forecasting cycle to incorporate this market knowledge in the forecast calculation. However, in the case where forecasting is done in-house, you could exceptionally recalculate your forecast to see the impact on your baseline right away and adjust your supply chain operations to mitigate it.

Second, forecasting is also about incorporating market knowledge to your demand prediction, and who, if not your internal demand planning team, can do this task better? Over time, demand planners have acquired relevant company- specific knowledge that should not be ignored. Having the knowledge of why the forecast values look like they do enables fully informed decision-making, increasing the degree of visibility and transparency across the supply chain network.

Third, in-house forecasting means being in control of the company’s intellectual property, as sensitive data is not shared with external providers. In addition, the process becomes less complex because no data loads are required, which we have observed in some companies to be quite tedious to manage.

And last but not least, forecasting can be kept in-house and done in a simple way! There is no need for fancy algorithms to predict your future demand. Simple statistical forecasting methods are, at least for repetitive decisions, typically superior to expert judgements. They are also easy to understand and are therefore easier to add input to. Thus, proactive and robust sales forecasts can be created by combining simple and easy-to-understand statistical forecasting methods with the market knowledge of the people in the organisation. With simple statistical methods, higher stability can be achieved, enabling better decision-making. We have seen that with outsourcing, forecast results vary significantly from one release to the next, making it difficult to make consistent decisions over time. However, when forecasting is done in-house using simple methods and applying simple criteria and rules, we can achieve a more stable forecast signal, thus allowing a superior decision process.

Simple forecasting brings robust accuracy and control to your forecasting process

Based on our experience, we only need a few simple elements to get a solid demand forecast.

Simple forecasting consists of generating a statistical baseline with a simple statistical method, such as the single exponential smoothing, and adjusting it based on seasonality, trend and market intelligence from Sales and Marketing. In essence, simple forecasting is about leveraging the benefits from statistical forecasting and the human judgement combined in a simple and efficient structure. This can be done through segmentation principles, making it easy for demand planners and other input givers to focus their effort in the forecasting process where it matters the most.

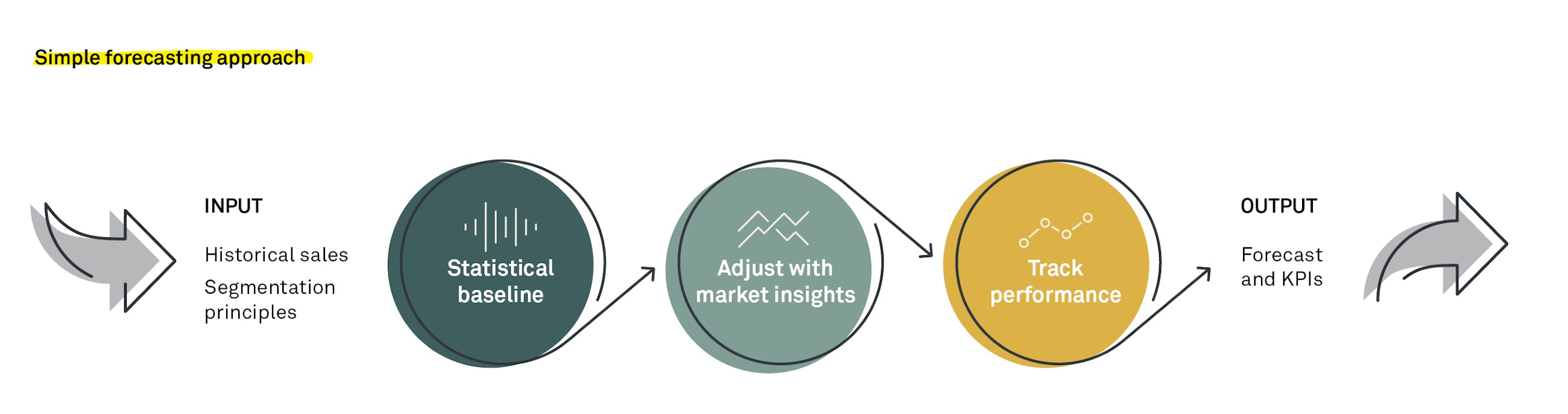

A typical simple forecasting approach that we recommend for the monthly demand planning process consists of three simple steps.

Historical sales data is used to calculate the forecast baseline generated with a simple statistical method such as the single exponential smoothing technique and applying seasonality and trends on top.

Historical sales data is also used to define a segmentation of the product portfolio based on their planning characteristics (typically, impact and predictability of sales). The resulting clusters or segments are used to focus the efforts on enriching the forecast by demand planners (in step 2) as well as enabling a common language for communicating across supply chain operations.

The output of the statistical forecasting generation is then reviewed and adjusted supported by the segmentation principles. That is, according to the different pre-defined simple segment rules, the input givers provide market insights into the forecast focusing on impact. For example, a high-runner item with a quite stable sales pattern will be easier to predict with statistical methods and will require less attention than a high runner with more volatility in sales.

Finally, the last step in the simple forecasting approach is to monitor the forecast performance with the use of standard reports and KPIs. These analysis tools will help planners identify potential issues in specific products or for specific time periods, focusing their efforts even more to achieve higher forecast performance. These tools can also help monitor the forecast accuracy and drive future behaviour in the demand planning process.

All in all, the most accurate forecast with the lowest bias and the highest stability is therefore a combination of very simple and understandable statistical forecasting, market intelligence, including opportunities and risks based on simple rules that enable incorporation of market insights into the sales forecast.

Conclusion

To conclude this reflection and answer to the initial question posed: “Should forecasting be kept in-house or outsourced to third-party providers?”, our answer is clear: Keep forecasting in-house and do it in a simple manner!

We have seen how enriching an outsourced forecast coming from a “black box” calculation with market intelligence is incredibly challenging. Therefore, a simple approach is needed. There is scientific evidence that the best forecasting models are simple – and if you simplify your forecast process, there is no reason for outsourcing it.

On the other hand, if you lean towards using advanced statistical methods with machine learning or AI, these “black box” calculations need to be owned in-house to ensure a better understanding and enable dialogue supporting the decision-making process.

Good luck with your demand planning improvement journey!

Case example

How did LEO Pharma improve the forecasting process by keeping it in-house and utilising the simple forecasting approach?

LEO Pharma, a Danish leading company in the pharmaceutical sector with sales in more than 100 countries worldwide, was in a situation where demand planning was in focus, seeking to improve their sales forecasting process. In this context, two very different approaches were considered; outsourcing forecasting capabilities to a third-party provider or implementing an improved statistical forecasting process in-house.

A project took place supported by a joint team of LEO Pharma demand planning experts and Implement consultants aiming at defining which forecasting strategy LEO Pharma should pursue. Based on an extensive analysis consisting of simulations based on actual data, it was proven that a simple forecasting approach would have provided a more accurate result than the historical manually generated forecasts. The simple forecasting approach was a combination of segmentation concepts with simple statistical methods and was supported by the tools and systems already in place.

The conclusion resulting from this assessment was clear: LEO Pharma should keep their forecasting in-house, utilising the already existing resources and expertise, and simple forecasting should be implemented. An implementation approach was designed and put in place in a short time. The transition towards simple statistical forecasting is in the process of being rolled out, and LEO Pharma is already starting to benefit from the first improvements in forecast quality and stakeholder satisfaction. As LEO Pharma’s regional supply chain manager for Europe says:

”I see the implementation of statistical forecasting in LEO Pharma as a key part of the overall journey to improve forecasting processes and accuracy. The transition has been a very good experience for us.”

LEO Pharma is a pharmaceutical company with a global team of 6,000 people serving 92 million patients in 130 countries. Headquartered in Denmark, LEO Pharma specialises in pharmaceutical products for dermatology and thrombosis. For more than 100 years, LEO Pharma has been using patient insights to research and develop new, safe and effective medicines to treat skin diseases.