Five selected features of the 2005 upgrade of SAP IBP

26 May 2020

On 1 May 2020, SAP released the 2005 upgrade of SAP Integrated Business Planning (IBP). We have compiled a staff-picked list of five features of the IBP 2005 upgrade that we think your company can benefit from and that can leverage your supply chain planning to the next level.

Five selected features of the 2005 upgrade of SAP IBP

1. “Go offline” mode in excel – share Excel with users that do not have IBP

Due to COVID-19, most companies have been “forced” to enhance virtual collaboration on various platforms, and now SAP IBP also offers enhancements for the interactions between IBP users and non-IBP users.

One of the key strengths of SAP IBP has been the interactive and collaborative planning in SAP IBP among IBP users, e.g. sharing favourite planning views, scenarios, alerts etc. With the new “go offline” mode in Excel, SAP IBP now enables SAP IBP users to easily share planning views with non-SAP IBP users. Non-SAP IBP users that do not have access to the Excel planning views can now open and work with the planning views (e.g. update key figure values) with normal Excel functionality and send them back to the IBP users as Excel workbooks. After receiving the Excel workbook from a non-SAP IBP user, the IBP user with access to the online functionalities can then turn on online mode and upload the input from the non-SAP IBP user to the IBP back-end system.

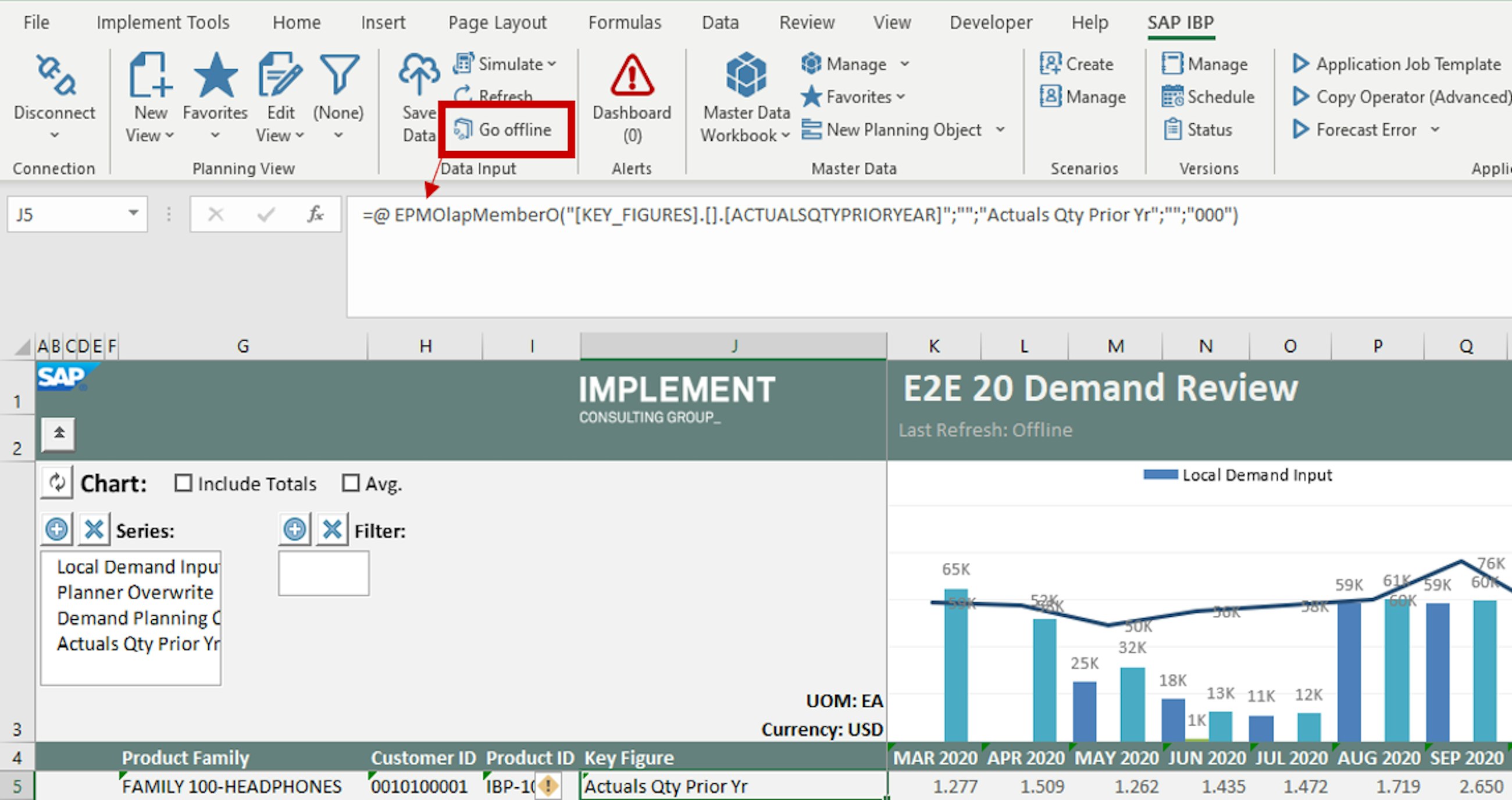

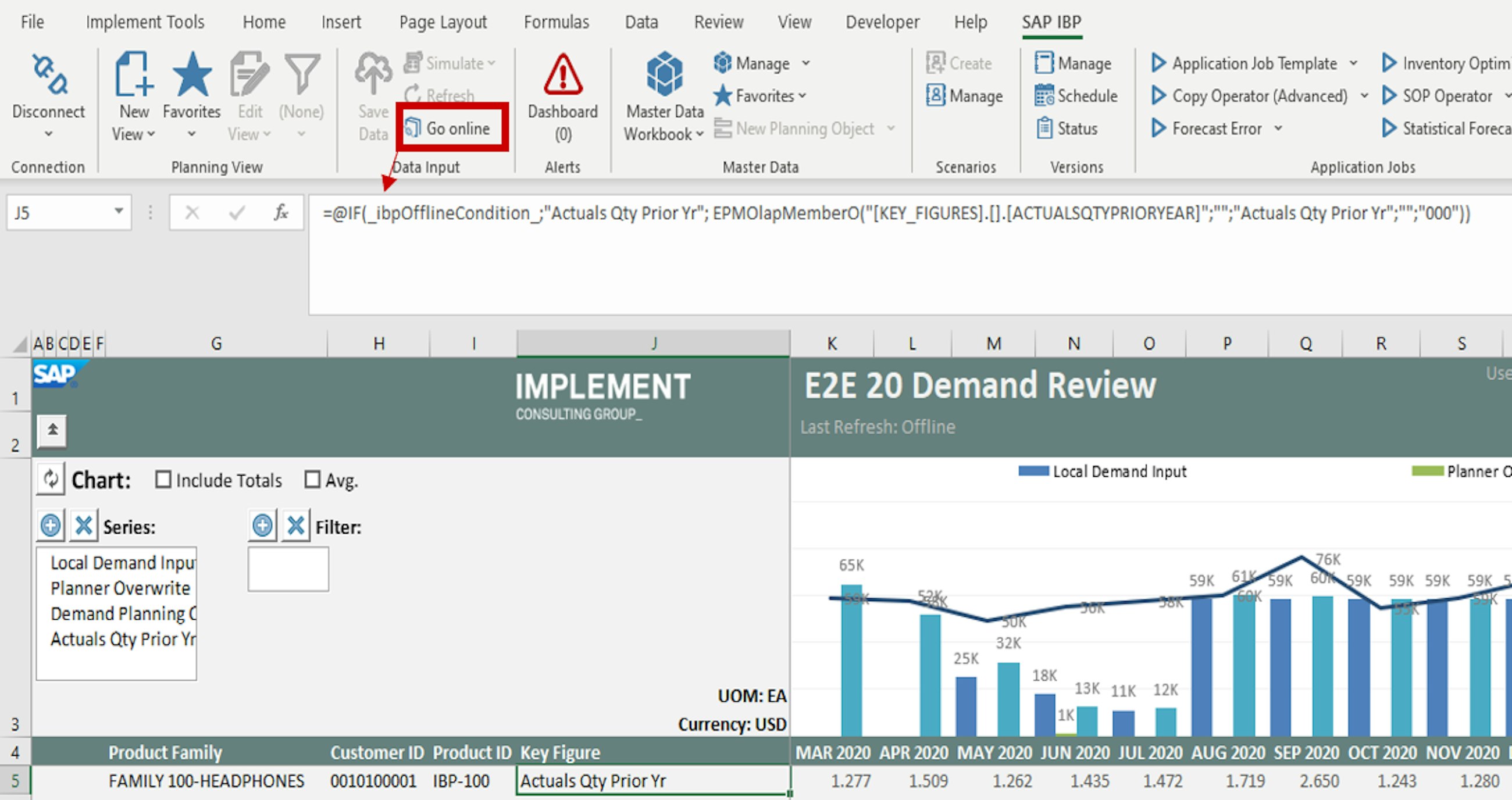

Using the “go offline” button in the “data input” group of the IBP ribbon, users can now convert their current workbook, including all sheets, to a “normal” Microsoft Excel workbook that does not contain the IBP references and formulas.

Now you probably ask yourself: “What happens to my IBP planning view when I share it with colleagues that have no idea of the structure behind SAP IBP planning views?” The answer is simple: in addition to the sharing functionality, SAP IBP has also protected the IBP workbook so that non-SAP IBP savvy colleagues cannot make changes which will harm the structure of the workbook and make it impossible to switch to “online mode” again and upload the changes.

Another enhancement to the new planning views is that the SAP IBP plug-in will be a standalone and not based on the EPM add-in that you know from earlier releases. SAP has made an on-the-fly conversion for your existing IBP templates, so no fixes are needed for your current templates.

However, when users with the new plug-in installed update a template, users with an older version of the IBP plug-in can no longer read the new and updated templates. For this reason, we strongly advise our clients to install the new add-in for all users simultaneously to counter the incompatibility of data/templates saved with new vs old plug-in.

2. Planning with calendars - define open and closed periods for production and transportation

In the previous release inbound calendars was introduced leaving supply planners with wishes for the introduction of production calendars to define open and closed periods for production resources and transportation. We also wrote that we would have our fingers crossed for the production calendars, so with perfect timing SAP provides a small for gift for supply planners! At a time where everything is closed down, SAP has now released the production and transportation calendars in the 2005 release – so planners can work with non-working days in the production and transportation calendars – a functionality that might seem even more relevant than before.

The introduction of production calendars enables supply planners to plan the production and transportation including non-working days. The production calendars are only available when working with the supply planning optimiser and the supply planning finite heuristic. The transportation calendar, on the other hand, works with the supply planning optimiser, supply planning finite heuristic and the supply planning infinite heuristic. The algorithms acknowledge that the production or transportation process cannot start or end in non-working periods, so it brings forward the start of the production process, so that it starts and ends in a working period. This potentially extend the production or transportation lead time, so it gets longer than the lead time defined in the Master Data.

In many cases planners will experience that production sources with lead times longer than one period gets interrupted by non-working periods. In cases like that the planning operators also brings the start of the production process forward to the first available working period.

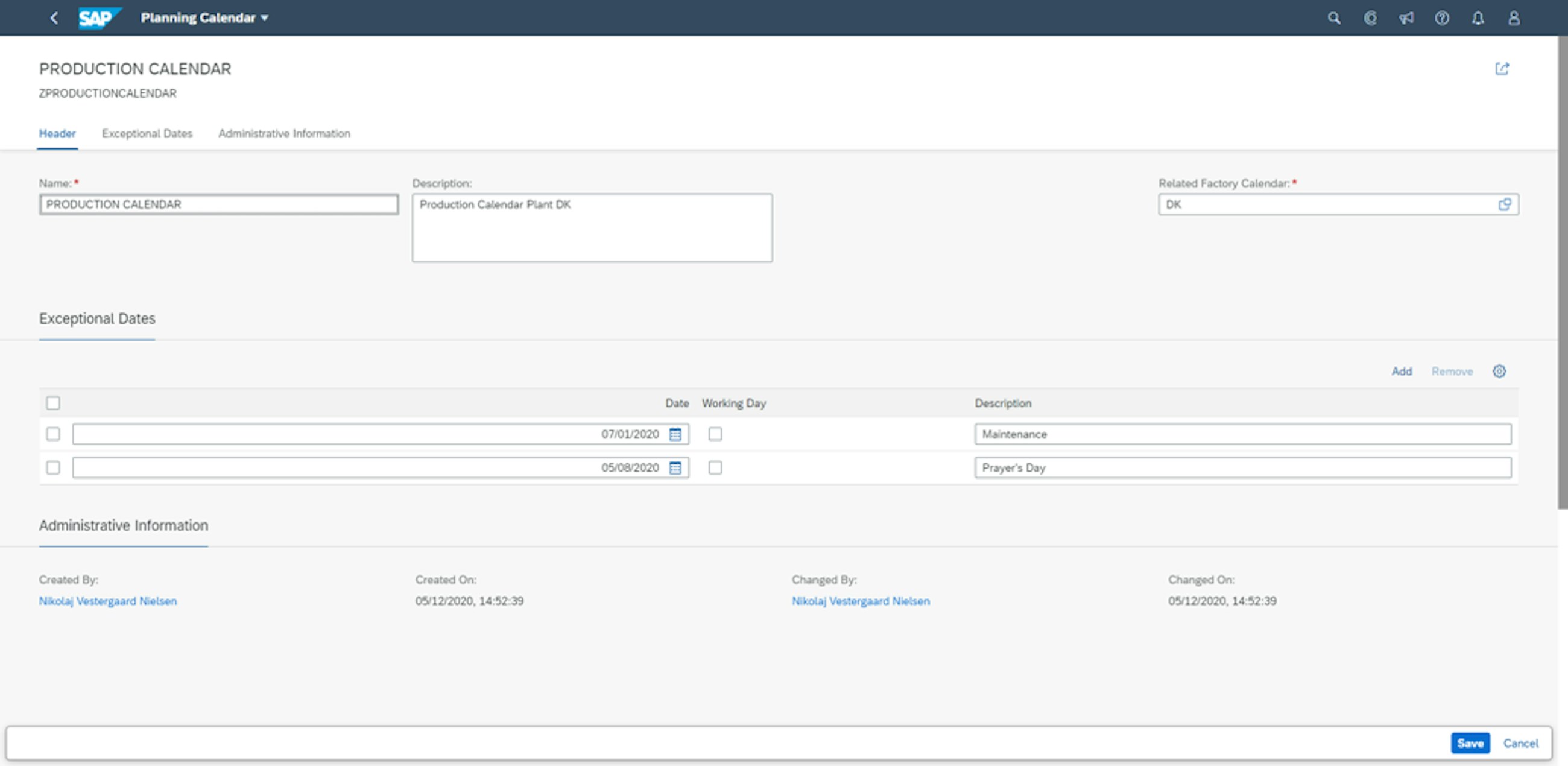

Just as with the Inbound Calendar, you need to create the Production or Transportation Calendar, by using the new Planning Calendar App. Create the calendar and make a reference to a SAP standard factory calendar. The standard factory calendars are now in IBP and by referencing one of those, you will have the default working days for that region.

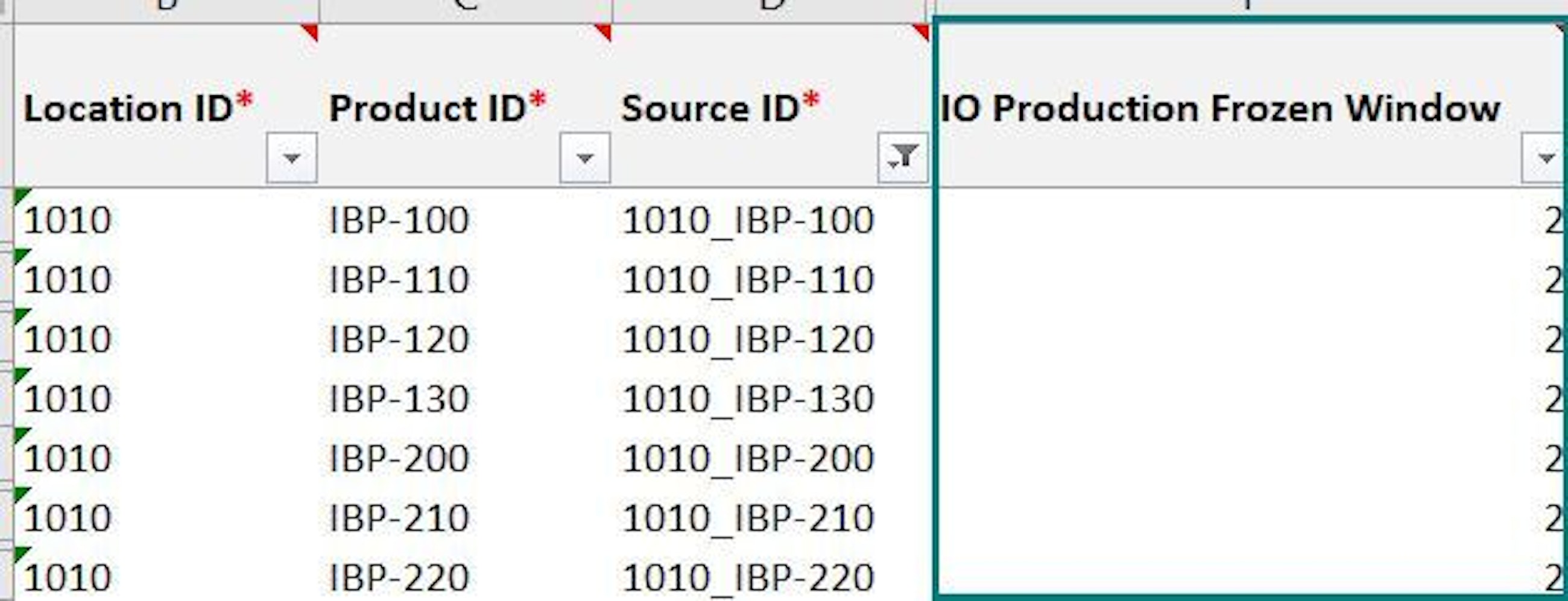

When you have created the calendar are you ready to add it to the master data in IBP.

If the configuration is not done yet for the Production Calendars, this should be done first. Create an attribute (Calendar Type) called PRODUCTIONCALID and add it to the Production Source Master Data Type.

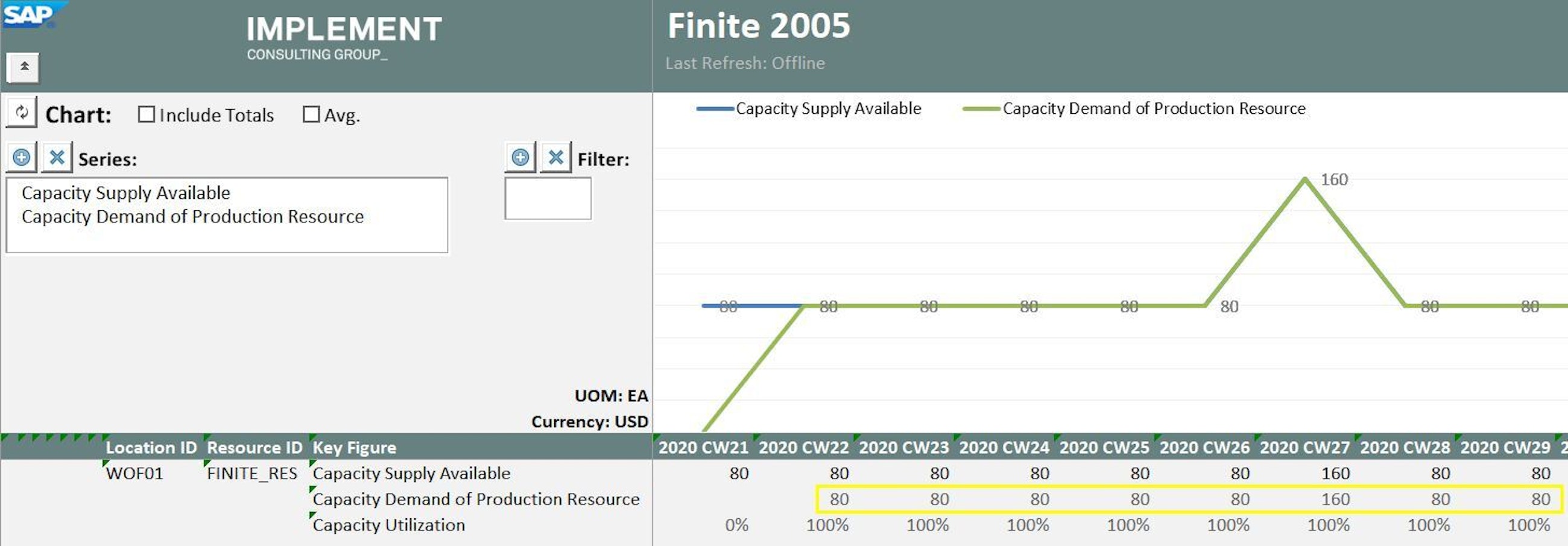

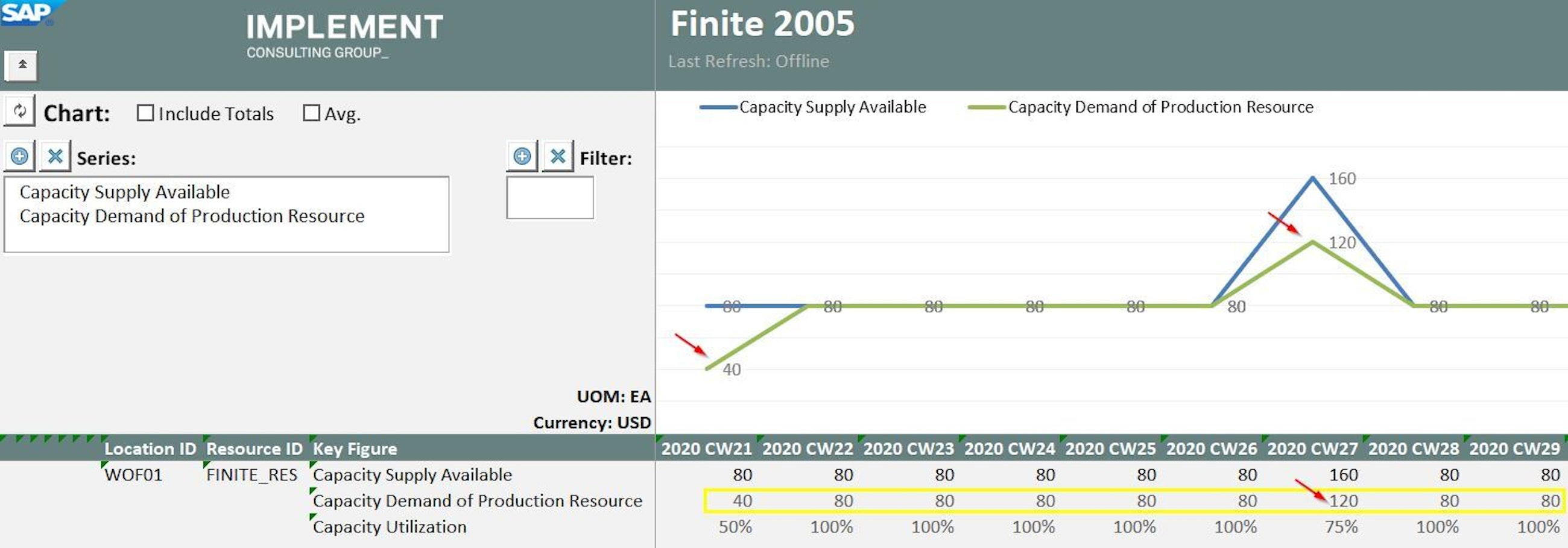

3. New functionalities are now available for the finite heuristic

If you follow our blog, you probably already know about the finite heuristic – the newest IBP time series planning operator, which enables creating a constrained supply plan based on priorities. In our post on the 1911 upgrade, we highlighted some of the limitations of the finite heuristic, which is why we are now very excited to write about the newest enhancements.

With the 2005 upgrade, the new heuristic type supports new settings previously not supported:

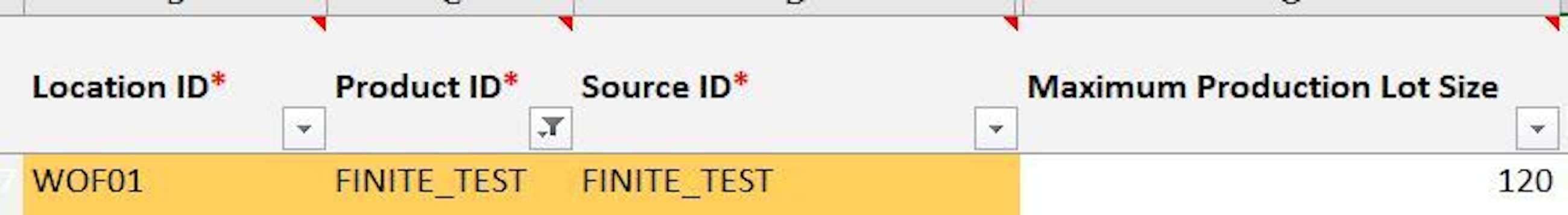

- Maximum lot sizes for production and transport

- Time-dependent production source item ratio

Before, the heuristic used the values of the current period and assumed it to be constant over the entire planning horizon. - All capacity consumption policies

Previously, number 2 was not supported. This means that when production lead times are long, you can now model the capacity usage of a production resource in each period of the production process rather than only in the first period of production (policy 0) or in the last period (policy 1). - Excluding dependent location demand and dependent production demand when using the static periods of supply lot-sizing procedure

This means that you can now set up the heuristic to build up stock to cover only for the dependent customer demand of the defined number of periods.

Despite these recent enhancements, the finite heuristic still has some limitations: it does not yet consider other time-dependent features such as transport and production costs, and it also does not consider dynamic periods of supply lot-sizing procedures, aggregated constraints and other settings used by its optimiser “cousin”. In the future, we expect this heuristic type to be enhanced further and further, and we will keep an eye on the coming releases.

4. Three new enhancements to inventory optimisation

With this latest upgrade, the SAP IBP inventory solution has gained some very useful functionalities. Here, we have picked three that we believe to be significant improvements.

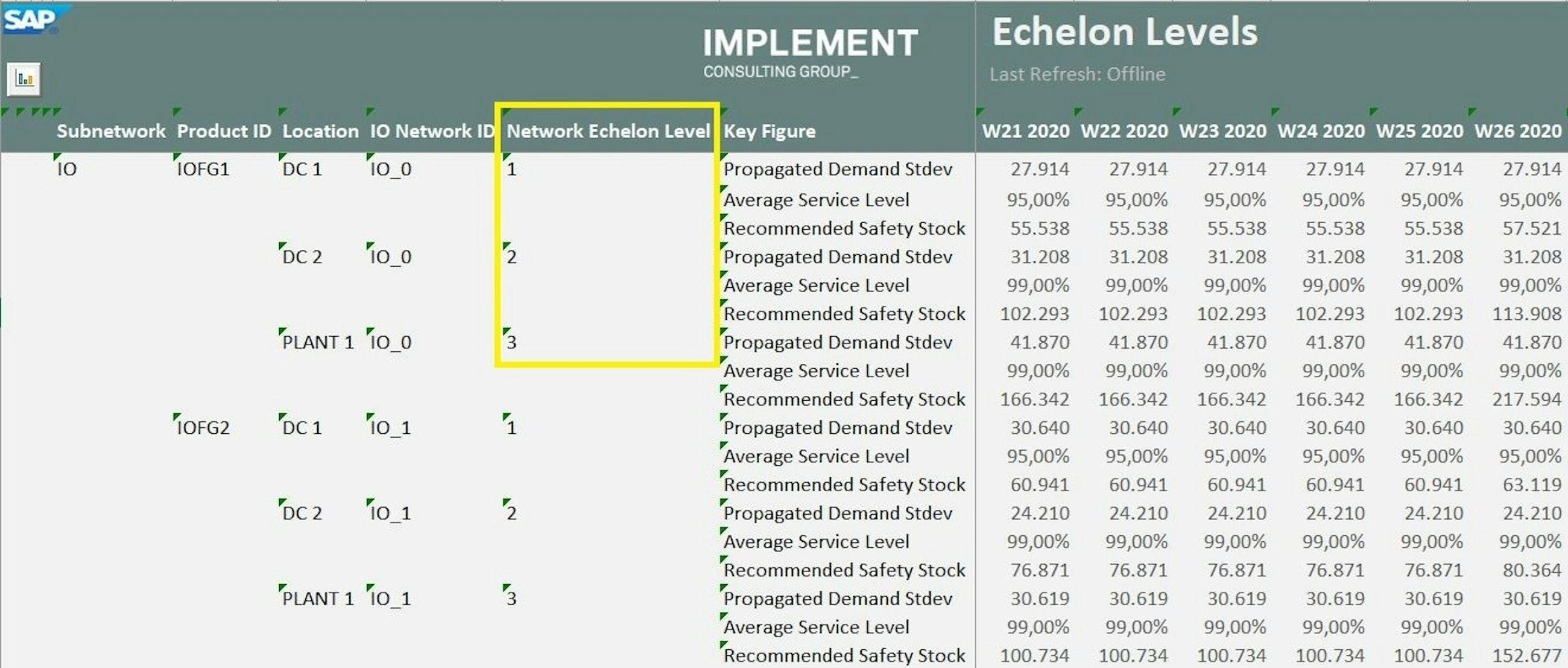

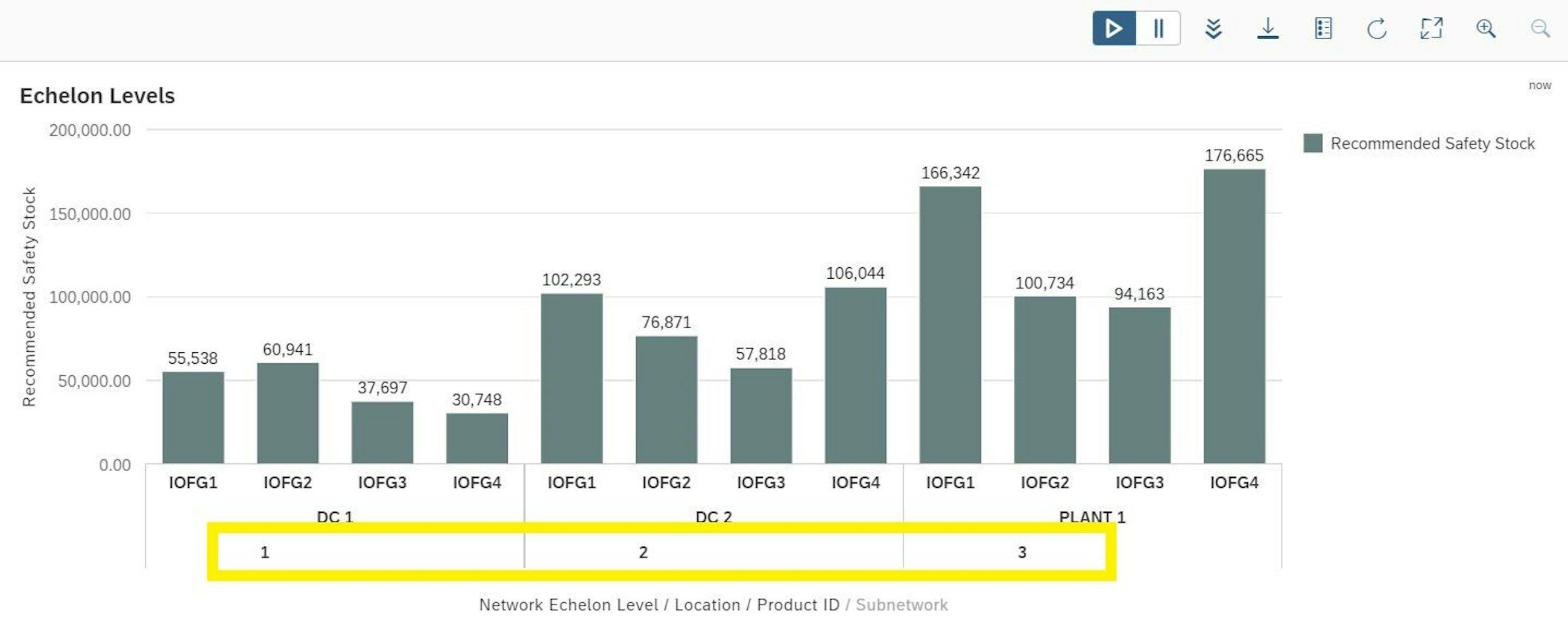

A new attribute helps validating the multi-stage optimisation results

To support the validation of the inventory optimisation results, SAP has now made a new attribute available: the network echelon level. This attribute, defined per product location, is automatically filled via the global inventory optimisation operator run. The attribute shows the number of echelon positions for each IO network ID, thereby making it easier to validate the inventory balancing results across a multi-stage network.

Frozen horizons can now be incorporated in inventory planning

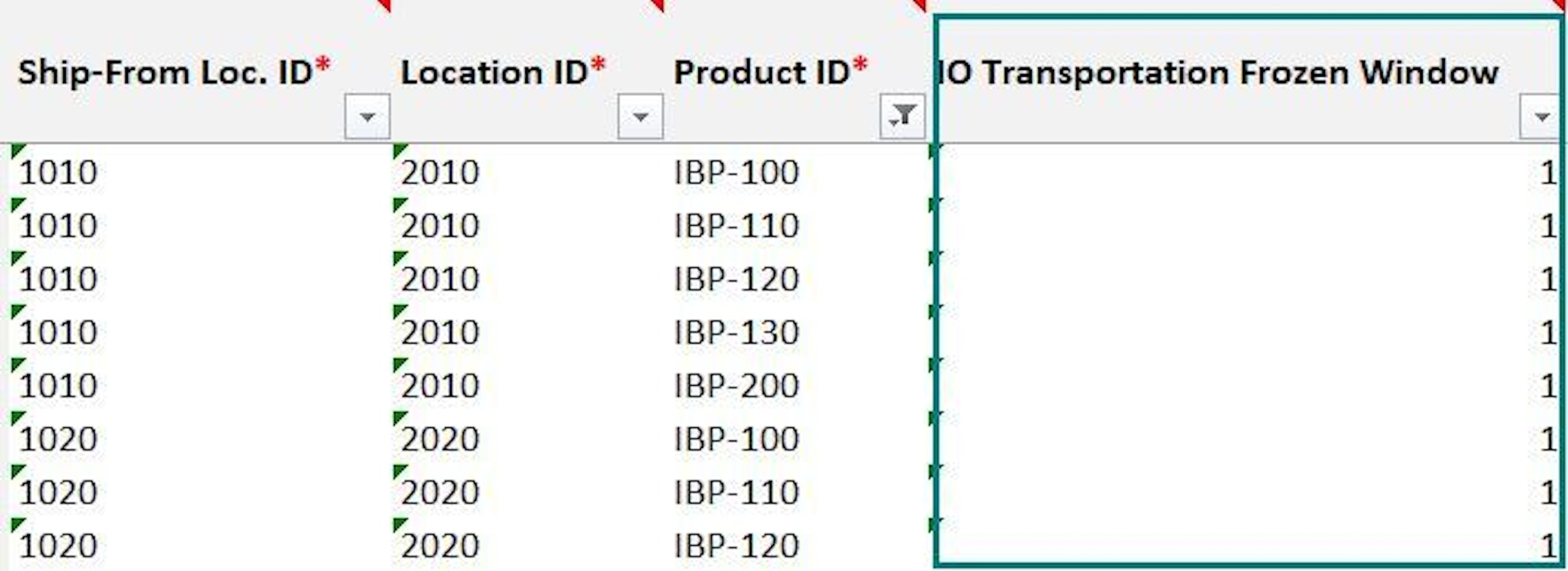

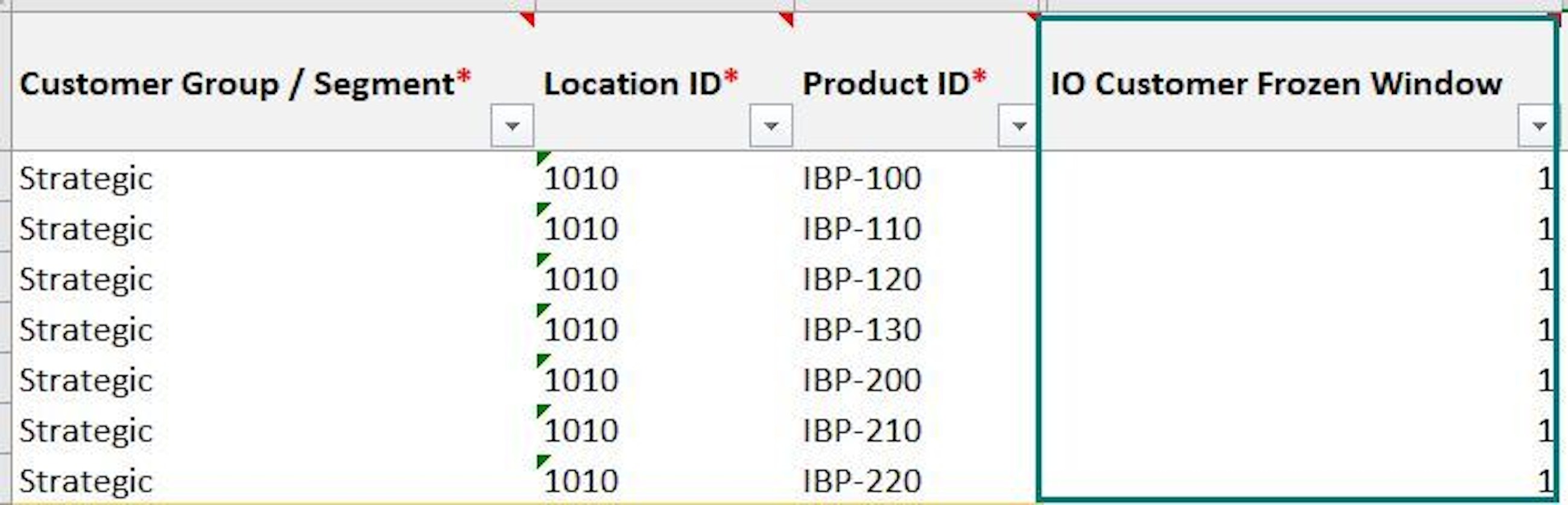

When planners want to create stability in the short-term supply plan and improve the synergies with the company’s execution system, they typically use frozen horizons: periods where changes to the plan cannot be made. Until this upgrade, you could set up frozen horizons in IBP in order-based planning as well as in supply planning for the transport, production and external supply plan.

Now you also get the possibility to use frozen horizon in inventory planning: the frozen periods in IO are enabled via three new attributes as key figures, allowing you to specify how many weeks of downstream demand forecast are frozen. This functionality is available for both the global (multi-stage) inventory optimisation and the decomposed (single-stage) inventory optimisation operators.

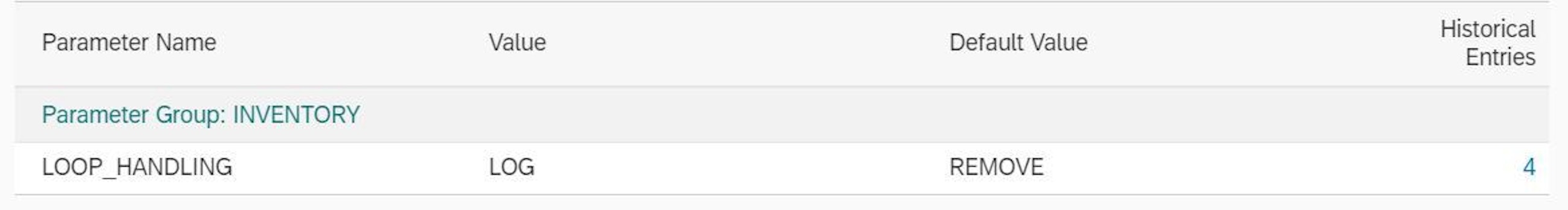

No more failing of the IO operator due to loops

The 2005 upgrade introduces another improvement for inventory optimisation regarding how cyclical sourcing (loops) is handled via the global configuration parameter for loops handling. The behaviour of the “REMOVE” parameter has now been modified, and after removing six levels of loops, any other additional loop is registered as warning rather than error. This means that now the operator does not fail when these additional loops are detected. Moreover, prior to the 2005 upgrade, this setting was only relevant for the global (multi-stage) inventory optimisation operator, whereas it is now considered also by the single-stage inventory optimisation operator.

5. Web-based planning gets a new feature

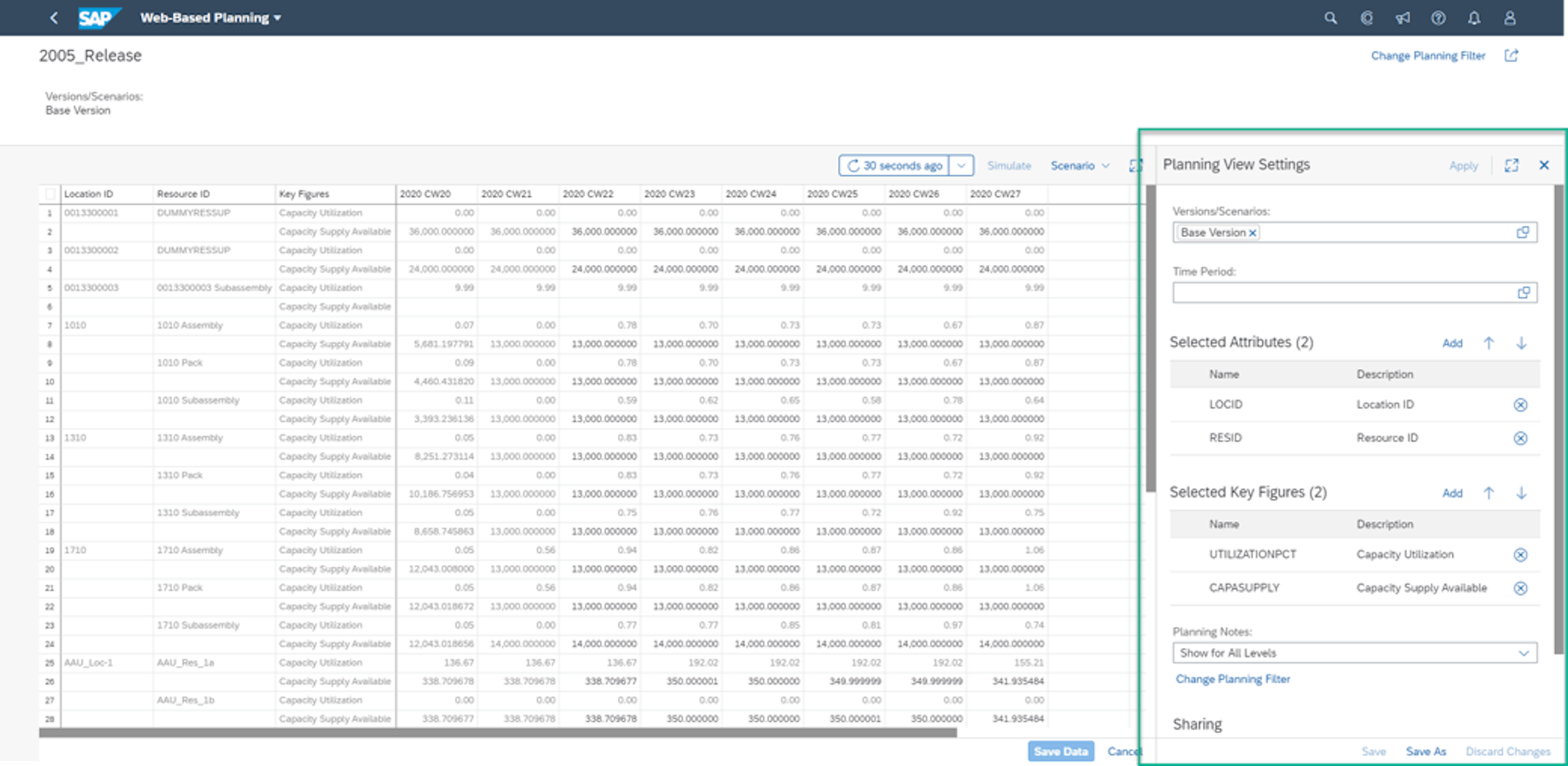

Another area of IBP that has recently gained more attention is the web-based planning. In the 2005 release, SAP has made enhancements to the web-based planning. The planning app got a usability upgrade with grid and planning views on the same screen. This means that planners no longer need to navigate away from the planning views when they want to change the settings. You can now change settings, apply the changes and check the results on the fly. The side panel in the planning view allows the planners to change attributes, key figures and filters on the go without leaving the planning view.

In addition, planners can now show order information from order-based planning in the web-based planning app. IBP users can show the orders in the web-based planning app and show certain key figure values, helping the user to understand the results of a planning run.