Challenges and opportunities for supply chain decarbonisation of the fashion industry

6 April 2022

With an increasing societal awareness of the environmental impact of production and consumption of fashion apparel, the fashion industry is facing a major transformation. Regulations and policies are adopted at a high speed to mitigate the worse effects of climate change while the industry is struggling to find the right actions at a feasible cost. Here, we will explore the challenges and opportunities related to the reduction of GHG emissions in the textile industry supply chain.

The fashion industry faces an immense transformation to mitigate the climate footprint of the industry. Several forces are simultaneously driving the necessary transformation, some of them being regulations at a national and international level, consumer demand for sustainably produced products, investor demands, resource scarcity as well as the opportunity to maintain a profitable business.

According to Intergovernmental Panel on Climate Change (IPCC), we need to cut GHG emissions by 45% from 2010 levels by 2030. Every industry has a part to play. Especially the fashion industry. According to the UNECE, 8-10% of the yearly global emissions are emitted by the fashion industry, and the trend is not going in the right direction1. In addition, textile and garment production is not only a carbon-intense operation, but also water-polluting, soil- and wild habitat-degrading and heavy in the use of hazardous chemicals.

Our consumption patterns are determined by fast fashion, contributing to an always evolving industry. Most fashion companies rely on a linear business model and value chain, optimised for high volume at low cost, driven by constant consumption of virgin resources to keep up the demand of new trends. In this business, the financial loss of an empty shelf is multiple the cost of overproducing. It is estimated that empty shelves result in loss of annual sales up to 4%. It is also evident that consumers will for eternity request fashion – it is a way for us as individual human beings to express ourselves and distinguish ourselves from others. Human beings will therefore always demand new clothes or ways to express themselves and use money on that.

Nonetheless, the existing way of operating cannot continue! Even though we see that the traditional notion of fashion seasons is fading and that movements towards sustainable consumption, re-use and vintage are booming and flourishing, examples of sustainable brands are growing and the business logic of wear and tear remains indisputable in the first place.

The challenge and the change are complex, and the whole industry of fashion must be addressed. From improving raw material extraction and agricultural practices, the type of energy used in production to creating alternative business models and consumption patterns.

There are two major cornerstones in a successful decarbonisation journey in the fashion industry

Based on experience, we see two key elements that we believe combined will drive the transformation of fashion industry emissions:

- Disrupting the existing business model – revolutionise business logic on how apparel products are sold and consumed.

- Delivering the business models via reduction of GHG emissions – decarbonise the supply chain, own operations and the customer use phase of the product.

Conditions for decarbonising global fashion supply chains are improving

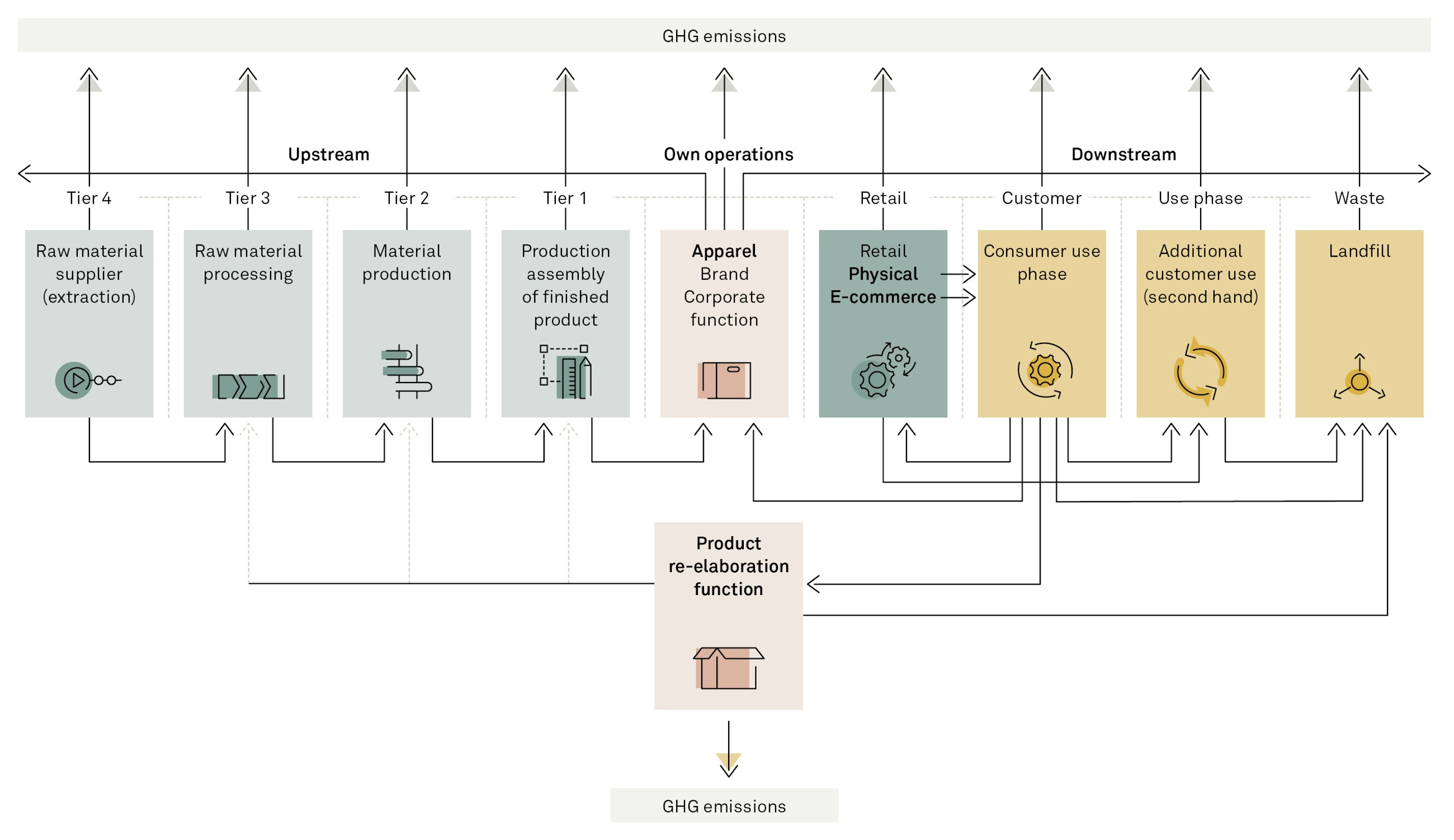

Apparel has a long and articulated supply chain (see figure) formed by a sequential level of suppliers. Each tier of suppliers contributes to the total GHG emissions, some more than others.

Studies have shown that tier 2 suppliers (material production) alone, as an example, account for 45%2 of the upstream emissions in the supply chain of the apparel industry. In total, the upstream supply chain activities account for 71% of the GHG emission while only 6.2% of emissions come from fashion brands’ own operations.

Previously, companies have faced some major obstacles to implementing solutions mitigating GHG emissions. These have been high cost and long implementation processes, weak regulatory direction as well as lack of financial resources and knowledge to drive the movement. Also, it is noticeable that there has been an absence of a regulatory framework for decarbonising the fashion industry compared to other industries, which is delaying the incentive for creating viable solutions.

But now, conditions are changing both globally and across the industry; the costs of decarbonisation solutions are decreasing, and it is becoming easier to implement tested solutions. In fact, it is estimated that major global supply chains, like fashion, can be decarbonised with readily available technologies at low end-to-end costs. For the fashion industry to reach net zero by 2050, it would cost more than $1 trillion to acquire and implement the range of solutions. However, the transition can be swift as it is anticipated that around 60% of the investment would be to existing solutions, ready to implement, where the remaining 40% would be to develop, scale and implement innovative solutions3.

Opportunities to decarbonise fashion supply chains

We acknowledge that the overall value chain is super complex and uncontrollable. Therefore, decarbonisation might only be feasible for parts of the production. Nevertheless, we see some actions that the fashion industry can dive into right away. We do acknowledge that the solutions might look different between companies – especially when targeting the mass market.

We have identified and outlined some of the major challenges and consequent opportunities related to up- and downstream supply chain/own operations decarbonisation.

Upstream supply chain decarbonisation

- Facilitating supplier dialogue to incentivise target setting for the decarbonisation of material production and improved material mix, processing and garment manufacturing, consequently steering focus towards minimising production and manufacturing waste.

- Ensuring supplier engagement and partnerships on innovation projects with suppliers from tier 1 and beyond.

- Routinely screening suppliers based on sustainability targets to ensure compliance with own sustainability targets.

- Engaging in innovations such as substituting virgin materials with new sustainable fabrics will really reduce the negative impact.

Own operation decarbonisation

- Planning and operational efficiency to minimise returns, reduce overproduction and waste creation.

- Initiating a materiality assessment, carbon baseline and material lifecycle cost to identify best sustainable option for decarbonisation.

- Data collection and monitoring for reporting to ensure optimised and automatised emission reduction and reporting tasks.

- Training and capability building to close the gap of employees’ lack of knowledge and improve choices on product development.

- Creating support initiatives that enable refurbishment of apparel, production of long-lasting products, instauration of reward programme for consumers and embrace initiatives such as manufacturing to order.

- KPI setting and monitoring to control, monitor and improve sustainability targets year by year.

- Promoting a sales platform for reselling, incentives for second-hand use and sales.

Downstream supply chain

- Ensuring renewable fuelled or electrified distribution from suppliers and to clients.

- Educating consumers in choices, use of products and impact of the products. Promoting washing and drying actions.

- Promoting recycling and textile collection to feed and actively support businesses working with transforming waste to new raw material.

Bold commitments towards a change in business logic

To meet the targets of 1.5-degree reduction according to the Paris Agreement, the fashion industry should not only strive to decarbonise existing value chains. To ultimately succeed, the winning aspiration needs to go beyond the linear business logic, which involves redefinition of business models into circular ones that generate growth decoupled from resource consumption. A fully decarbonised value chain that continues to drive mass consumption of finite resources will simply not solve the bigger problem – neither will a circular value chain if it is based on “dirty” operations.

Therefore, the fashion industry must combine both supply chain decarbonisation quests and business model redefinition initiatives. Only in this way will we see a fashion industry that is truly promoting responsible consumption and growth according to the Paris Agreement. Meeting the 1.5-degree reduction is not only a matter of long-term profit maintenance but also a commitment towards our planet and people for a truly respectful triple bottom line.

Sources

2 https://www.sustainablefashionacademy.org/sites/default/files/stica_report_1.0_210323.pdf