95% of products fail – here’s how you avoid being part of that statistic

26 October 2022

Every year, 30,000 new physical products are introduced. But, according to the late Harvard Business School professor Clayton Christensen, only 5% make the cut. These are not good odds for anyone working in product creation.

No matter whether your company has a higher success rate (we hope it does) or worse (hang in there), almost every professional within product creation has experienced at least one launch that did not go as well as hoped.

In general, we see four main reasons why products fail after they hit the market:

- The product is hard to use

- The product’s cost equation does not work

- Customers do not know about the product

- Customers simply do not need or want the product

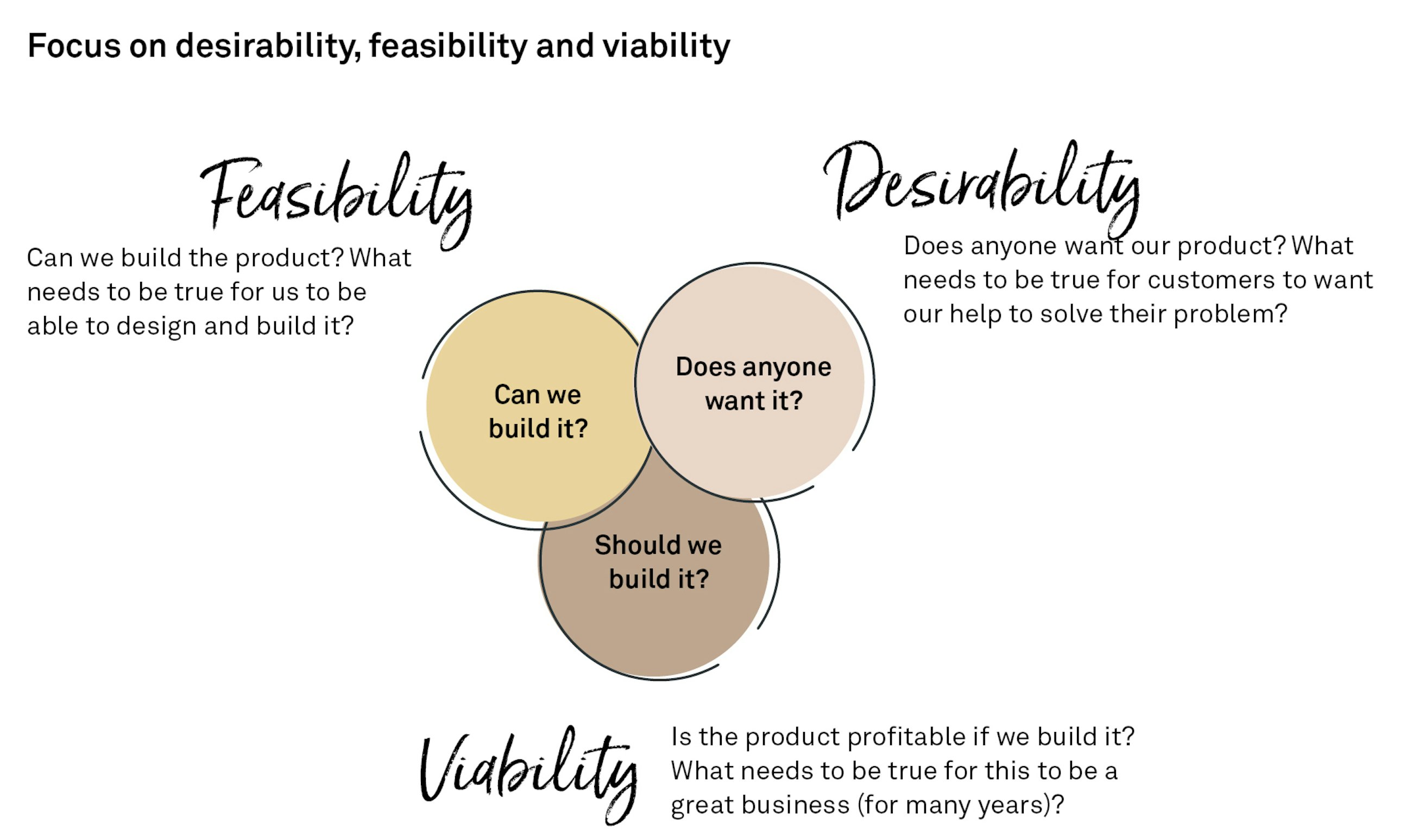

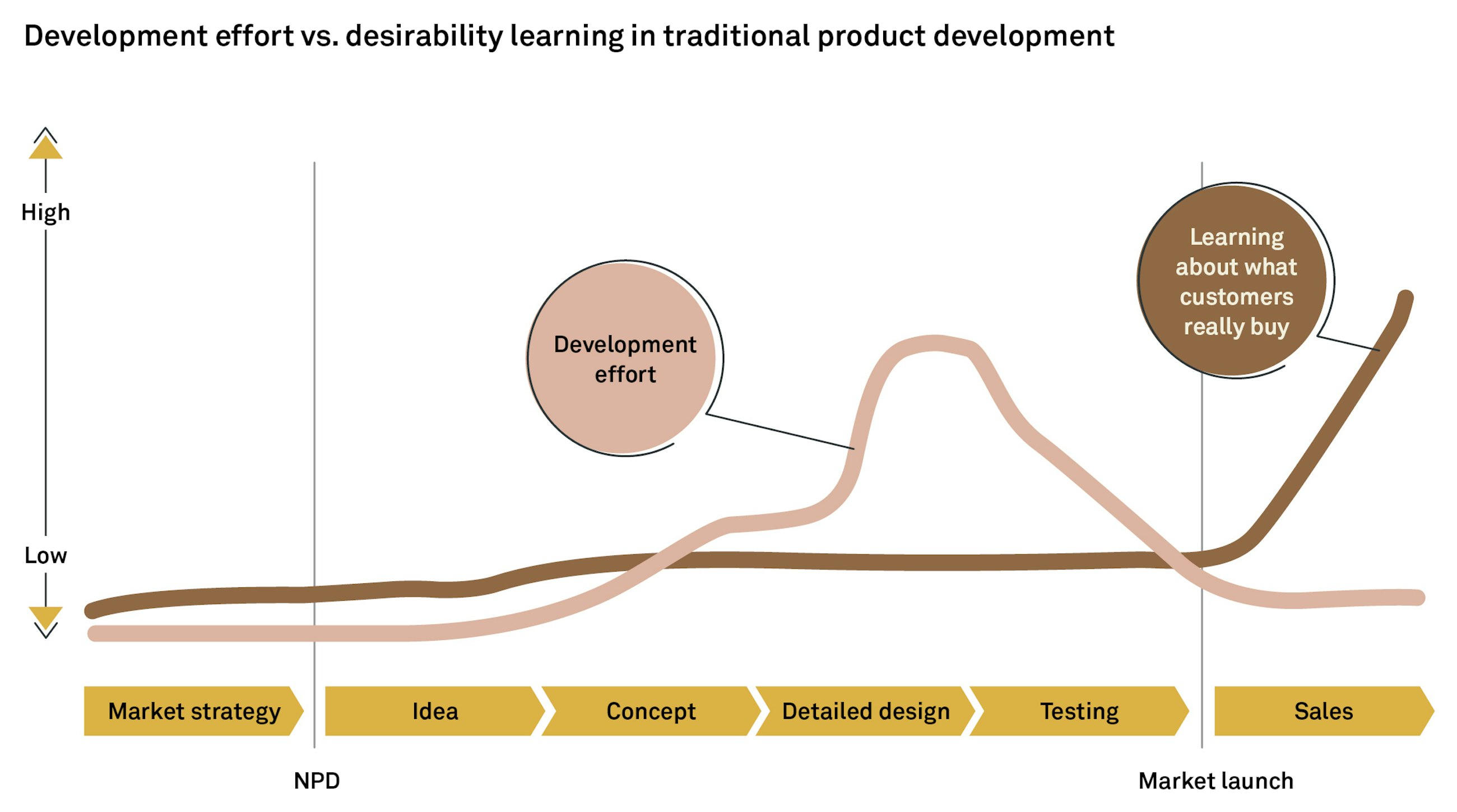

Businesses typically spend a lot of effort before and during product development to ensure the product’s feasibility and viability. Obviously, no one wants to launch an unusable or unprofitable product.

However, for many products, the true level of desirability only becomes apparent after launch , when customers are faced with it for the first time. Sometimes only for companies to discover that the expected need and want in the market is smaller than first believed.

If we do not have a strong understanding of the desirability dimension during product development, it often leads to desirability being bought after launch through a heavy marketing budget. Sometimes, this results only in short-lived success.

To ensure lasting desirability, there is an easier (and cheaper) way. You should focus on developing products your customers truly desire in the first place. And, as obvious as it may seem, the way to do this is to understand their real needs.

Key questions for understanding what customers want

- Jobs to be done: What functional, emotional and social jobs do the customer need solved

- Pains: What barriers or challenges are customers encountering when trying to solve their challenge

- Gains: What potential gains could customers experience when the job is performed very well?

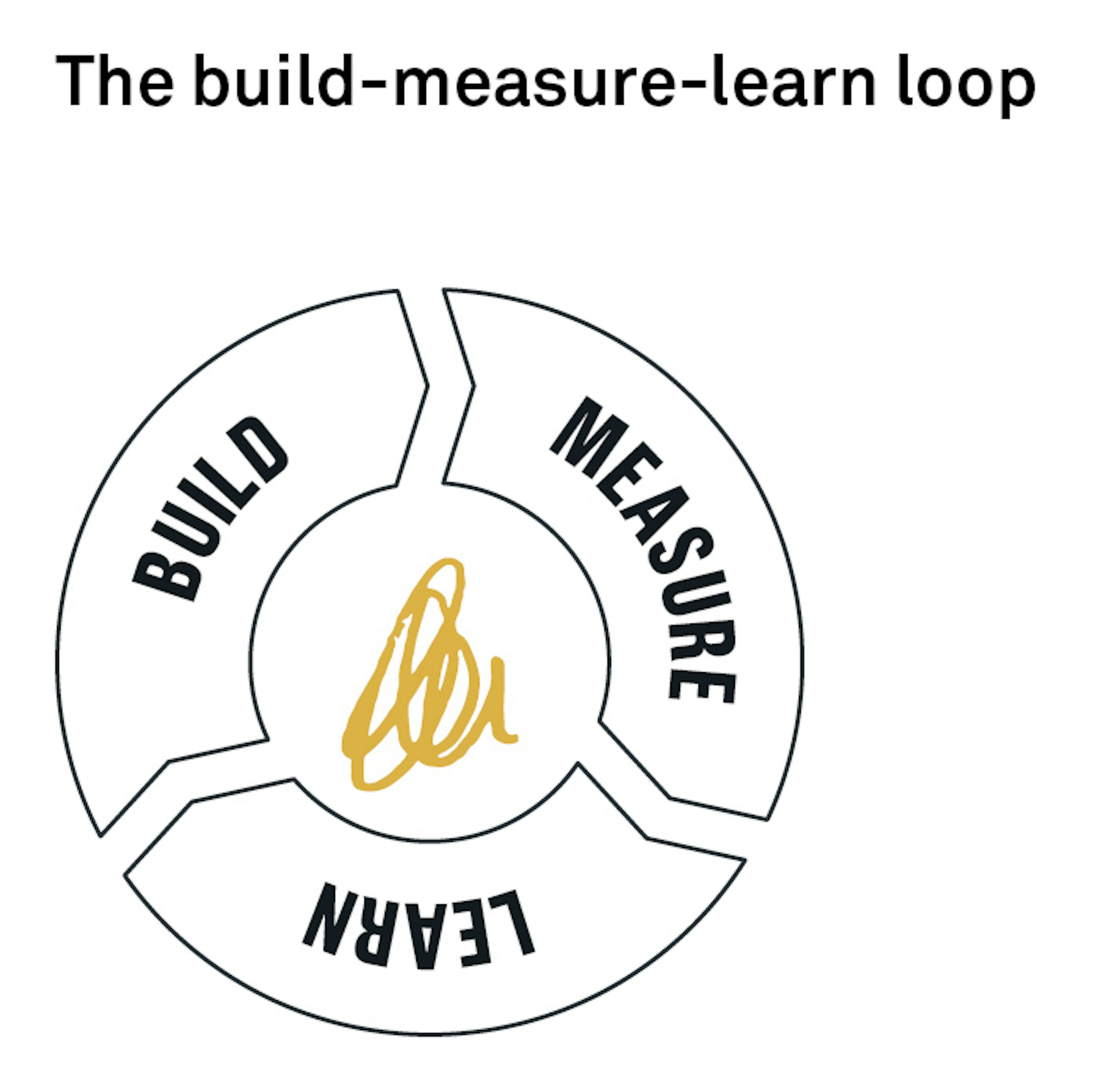

For those working in software development, the Lean Start-up methodology has long been the answer to avoiding undesired product launches. However, it has not been used widely in “physical-product” companies. We believe this is a mistake, as we see significant potential to be gained from using this methodology in conjunction with other frameworks to ensure customer centricity in physical-product businesses.

The foundational concept of Lean Start-up is to use the Build-Measure-Learn feedback loop, using testing to evaluate incremental adjustments to the product.

Think of your product as a “mini-business”

Any product, whether a stand-alone or just a new component, ultimately faces the same general market dynamics. It is therefore helpful to assess the product in a more holistic way – as if it was its own “mini-business”. You can do this by applying a framework such as the Business Model Canvas. The canvas will help you understand key questions such as: What is the value proposition of the product? What pains does it address, and for which customer segment?

Be (very) aware of your assumptions

Put simply, assumptions are unsubstantiated beliefs you have concerning the product. The tricky thing about assumptions is that they are often hidden in our blind spots. When you assess a product holistically, through a framework like the Business Model Canvas, you more easily become aware of what is known and what is not. Only by being very critical of your beliefs can you uncover true assumptions.

Test with your customers – early and frequently

You can test in a myriad of ways; from small-scale testing, such as a “fake” sales brochure, all the way to a fully working prototype. The testing effort should always reflect the development maturity of the product. The key to choosing the right test level is to ask: “what is the minimum viable test we can do to validate the assumption at hand?”

When testing, the most important thing to consider is to ensure that the output is in the form of do-evidence and not say-evidence. Asking a customer to assess whether they would buy a product will often lead to a “yes” – simply because it comes at no cost to them. But asking a customer to commit to a letter of intent, or even a pre-order, is much more difficult. And much more valuable.

Make decisions based on your testing

Testing alone brings you nowhere. To reap the value of your insights, they need to be transformed into decisions. Has the testing proved true desirability? Or have certain product attributes not proven valuable to the customers, suggesting a pivot? When a decision has been made, it’s time to enter the test loop again.

Or ultimately – did the testing uncover no true desirability at all? If so, it might be time to kill your darling before it becomes part of the 95%.

“The TV remote example”

In classic product development, another pitfall is creating overly complicated products.

Just think of the TV remote on your parent’s coffee table during your childhood. How many of those buttons did you ever really use? Now compare that to the well-tested Apple-TV remote.

Testing enables you to understand your customers’ actual need – and helps you avoid creating redundant features with no perceived value. This results in better streamlined products – and cheaper production costs.

Case study

Universal Robots (UR) is an automation company and a global leader in collaborative robot arms. They are on the cutting edge of integrating advanced software and hardware capabilities to deliver market-leading products.

“While reorganising our product creation organisation, we saw a need for a closer connection to customers and ultimately decreasing the time to market of UR products. To achieve this, we worked with Implement to design an approach to apply key elements of Lean Start-up, design thinking and other innovation methods to our software and hardware context.”

- Lars Agerlin, VP for R&D.

Implement helped UR’s product development teams to think more holistically about their products. The teams had strong competencies in feasibility and viability testing but lacked a common framework and language to focus on desirability. Through a 2-day training course, Implement facilitated the development of 10+ mini-businesses to gain a full understanding of their value proposition and identify their key assumptions. As part of the training, teams were then challenged to use real-world tests to validate assumptions, and they also received coaching on converting test results into decisions.

“I’m very happy with the way that Implement designed and facilitated the training journey for my teams. It was excellent to use our own product cases to connect the methodologies to our day to day.”

- Chris Behling, Director for Software Engineering in USA

In the weeks and months following training, coaching sessions were held with the participating product teams to anchor the learnings into their way of working.

“I’m very happy with the way that Implement designed and facilitated the training journey for my teams. It was excellent to use our own product cases to connect the methodologies to our day to day.”

- Chris Behling, Director for Software Engineering in USA

In the weeks and months following training, coaching sessions were held with the participating product teams to anchor the learnings into their way of working.